Page 134 - Rotating Machinery Pratical Solutions to Unbalance and Misalignment

P. 134

Rotating Machinery: Practical Solutions

processes. They are discussed in more detail later in this and the

following chapters.

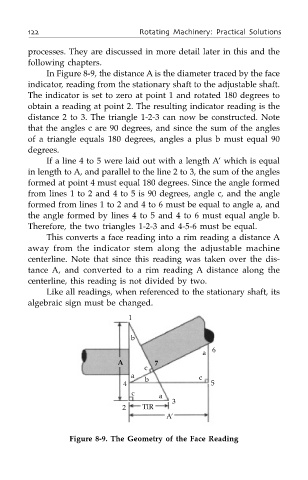

In Figure 8-9, the distance A is the diameter traced by the face

indicator, reading from the stationary shaft to the adjustable shaft.

The indicator is set to zero at point 1 and rotated 180 degrees to

obtain a reading at point 2. The resulting indicator reading is the

distance 2 to 3. The triangle 1-2-3 can now be constructed. Note

that the angles c are 90 degrees, and since the sum of the angles

of a triangle equals 180 degrees, angles a plus b must equal 90

degrees.

If a line 4 to 5 were laid out with a length A’ which is equal

in length to A, and parallel to the line 2 to 3, the sum of the angles

formed at point 4 must equal 180 degrees. Since the angle formed

from lines 1 to 2 and 4 to 5 is 90 degrees, angle c, and the angle

formed from lines 1 to 2 and 4 to 6 must be equal to angle a, and

the angle formed by lines 4 to 5 and 4 to 6 must equal angle b.

Therefore, the two triangles 1-2-3 and 4-5-6 must be equal.

This converts a face reading into a rim reading a distance A

away from the indicator stem along the adjustable machine

centerline. Note that since this reading was taken over the dis-

tance A, and converted to a rim reading A distance along the

centerline, this reading is not divided by two.

Like all readings, when referenced to the stationary shaft, its

algebraic sign must be changed.

1

b

a 6

A 7

c

a b c

4 5

c a

3

2 TIR

A’

Figure 8-9. The Geometry of the Face Reading