Page 63 - Rotating Machinery Pratical Solutions to Unbalance and Misalignment

P. 63

Vibration Due to Unbalance

When performing maintenance activities, care should be

taken to clean all buildup of dirt and debris from rotating compo-

nents, such as fan blades. Uneven buildup will result in an unbal-

ance that will lead to early failure of bearings and seals.

Example 4.3

A 6-foot diameter nodular iron flywheel weighs 8,634

pounds, and is assembled onto an engine’s crankshaft with bolts

in a 12-inch circle. During assembly, a piece of debris .001-inch

thick wedges between the flywheel and the crankshaft. The unit

operates at 300 rpm. How much force is generated as a result of

this misalignment of the flywheel?

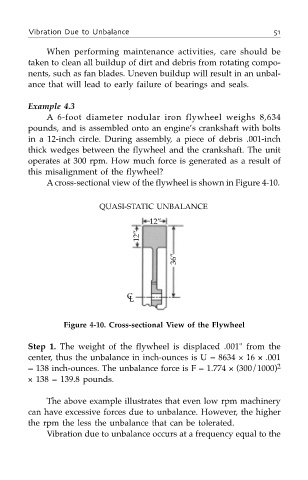

A cross-sectional view of the flywheel is shown in Figure 4-10.

QUASI-STATIC UNBALANCE

12”

12”

36”

C L

Figure 4-10. Cross-sectional View of the Flywheel

Step 1. The weight of the flywheel is displaced .001" from the

center, thus the unbalance in inch-ounces is U = 8634 × 16 × .001

= 138 inch-ounces. The unbalance force is F = 1.774 × (300/1000) 2

× 138 = 139.8 pounds.

The above example illustrates that even low rpm machinery

can have excessive forces due to unbalance. However, the higher

the rpm the less the unbalance that can be tolerated.

Vibration due to unbalance occurs at a frequency equal to the