Page 31 - Sensing, Intelligence, Motion : How Robots and Humans Move in an Unstructured World

P. 31

6 MOTION PLANNING—INTRODUCTION

that require motion planning. Robots in automotive industry are today among the

most successful, most cost-effective, and most reliable machines. Robot motion

planning algorithms have penetrated areas far from robotics, from designing

quick-to-disassemble aircraft engines (for part replacement at the airport gate)

to studies of folding mechanisms of DNA molecules.

It is the unstructured environment where our success stops. We have difficulty

moving robots into our messy world with its unending uncertainty. That is where

the situation is bleak indeed—and that is where robotics is needed badly.

The situation is not black and white but rather continuous. The closer a task

is to that in a fully structured environment, the better the chance that today’s

approaches with complete information will apply to it. This is good news. When

considering a robot mission to replace the batteries, gyroscopes, and some sci-

entific instruments of the aging Hubble Space Telescope, NASA engineers were

gratified to know that, with the telescope being a fully man-made creature, its

repair presents an almost fully structured task. The word “almost” is not to be

overlooked here—once in a while, things may not be exactly as planned: The

robot may encounter an unscrewed or bent bolt, a broken cover, or a shifted cable.

Unlike an automotive plant, where operators check out the setup once or twice

a day, no such luxury would exist for the Hubble ground operators. Although,

luckily, the amount of “unstructuredness” is small in the Hubble repair task, it

calls for serious attention to sensing hardware and to its intimate relation to robot

motion planning. Remarkably, even the “unstructuredness” that small led to the

project’s cancellation.

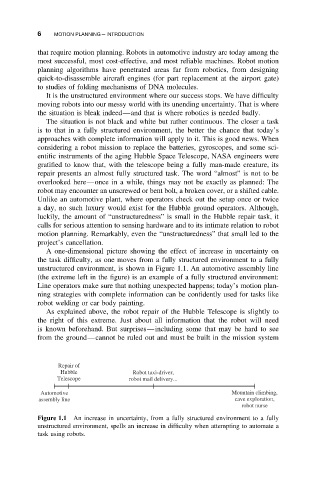

A one-dimensional picture showing the effect of increase in uncertainty on

the task difficulty, as one moves from a fully structured environment to a fully

unstructured environment, is shown in Figure 1.1. An automotive assembly line

(the extreme left in the figure) is an example of a fully structured environment:

Line operators make sure that nothing unexpected happens; today’s motion plan-

ning strategies with complete information can be confidently used for tasks like

robot welding or car body painting.

As explained above, the robot repair of the Hubble Telescope is slightly to

the right of this extreme. Just about all information that the robot will need

is known beforehand. But surprises—including some that may be hard to see

from the ground—cannot be ruled out and must be built in the mission system

Repair of

Hubble Robot taxi-driver,

Telescope robot mail delivery...

Automotive Mountain climbing,

assembly line cave exploration,

robot nurse

Figure 1.1 An increase in uncertainty, from a fully structured environment to a fully

unstructured environment, spells an increase in difficulty when attempting to automate a

task using robots.