Page 325 - Sensors and Control Systems in Manufacturing

P. 325

282

Cha p te r

S i x

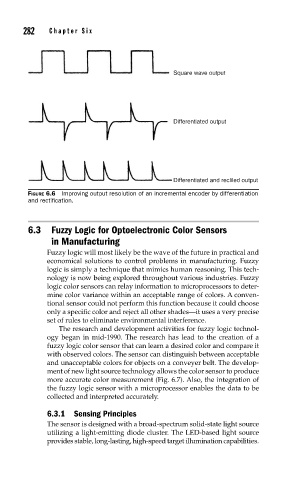

Square wave output

Differentiated output

Differentiated and recliled output

FIGURE 6.6 Improving output resolution of an incremental encoder by differentiation

and rectifi cation.

6.3 Fuzzy Logic for Optoelectronic Color Sensors

in Manufacturing

Fuzzy logic will most likely be the wave of the future in practical and

economical solutions to control problems in manufacturing. Fuzzy

logic is simply a technique that mimics human reasoning. This tech-

nology is now being explored throughout various industries. Fuzzy

logic color sensors can relay information to microprocessors to deter-

mine color variance within an acceptable range of colors. A conven-

tional sensor could not perform this function because it could choose

only a specific color and reject all other shades—it uses a very precise

set of rules to eliminate environmental interference.

The research and development activities for fuzzy logic technol-

ogy began in mid-1990. The research has lead to the creation of a

fuzzy logic color sensor that can learn a desired color and compare it

with observed colors. The sensor can distinguish between acceptable

and unacceptable colors for objects on a conveyer belt. The develop-

ment of new light source technology allows the color sensor to produce

more accurate color measurement (Fig. 6.7). Also, the integration of

the fuzzy logic sensor with a microprocessor enables the data to be

collected and interpreted accurately.

6.3.1 Sensing Principles

The sensor is designed with a broad-spectrum solid-state light source

utilizing a light-emitting diode cluster. The LED-based light source

provides stable, long-lasting, high-speed target illumination capabilities.