Page 328 - Sensors and Control Systems in Manufacturing

P. 328

Advanced Sensors in Pr ecision Manufacturing

molecules return (bend) incoming light. For example, a red pigment 285

causes a measurable hue component of the color. The relative density

of the pigment molecules leads to the formation of the saturation com-

ponent. Some molecules return almost all wavelengths, and appear

white as a result, leading to the intensity (lightness) component.

6.3.3 Units of Color Measurement

If color description depends on measuring the interaction of a target

color with a given white light source, it is clear that in order to have

the system of measurement standardized, both the light source and

means of detection must be well-defined. One very popular set of

standardization rules has been set up by the Commission Interna-

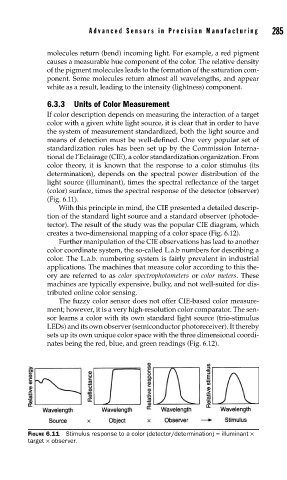

tional de l’Eclairage (CIE), a color standardization organization. From

color theory, it is known that the response to a color stimulus (its

determination), depends on the spectral power distribution of the

light source (illuminant), times the spectral reflectance of the target

(color) surface, times the spectral response of the detector (observer)

(Fig. 6.11).

With this principle in mind, the CIE presented a detailed descrip-

tion of the standard light source and a standard observer (photode-

tector). The result of the study was the popular CIE diagram, which

creates a two-dimensional mapping of a color space (Fig. 6.12).

Further manipulation of the CIE observations has lead to another

color coordinate system, the so-called L.a.b numbers for describing a

color. The L.a.b. numbering system is fairly prevalent in industrial

applications. The machines that measure color according to this the-

ory are referred to as color spectrophotometers or color meters. These

machines are typically expensive, bulky, and not well-suited for dis-

tributed online color sensing.

The fuzzy color sensor does not offer CIE-based color measure-

ment; however, it is a very high-resolution color comparator. The sen-

sor learns a color with its own standard light source (trio-stimulus

LEDs) and its own observer (semiconductor photoreceiver). It thereby

sets up its own unique color space with the three dimensional coordi-

nates being the red, blue, and green readings (Fig. 6.12).

FIGURE 6.11 Stimulus response to a color (detector/determination) = illuminant ×

target × observer.