Page 352 - Sensors and Control Systems in Manufacturing

P. 352

Advanced Sensors in Pr ecision Manufacturing

are used to sample and process the return signal. Lenses shape that 307

laser light into a plane wave incident upon the acoustooptical sensor.

The integration in space is effected at the moment of sampling by the

focusing action. The position of the focal point in the cell depends on

the range delay of the corresponding target, and light is brought to

focus on two CCD imaging arrays at positions that depend on the

range.

The sinusoidal reference signal component of the cell interacts

with laser radiation to generate a plane wave of light that interferes

with the light focused by the cell. This produces interference fringes

that encode the phase information in the range-compressed optical

signal. These fringes are correlated with a mask that has a predeter-

mined spatial distribution of density and that is placed in front of, or

on, one of the CCD arrays. This CCD array is operated in a delay-

and-integrate mode to obtain the desired correlation and integration

in time for the azimuth compression. The output image is continu-

ously taken from the bottom picture element of the CCD array.

Two CCDs are used to alleviate a large undesired bias of the

image that occurs at the output as a result of optical processing. CCD

1

is used to compute this bias, which is then subtracted from the image

of CCD to obtain a better image.

2

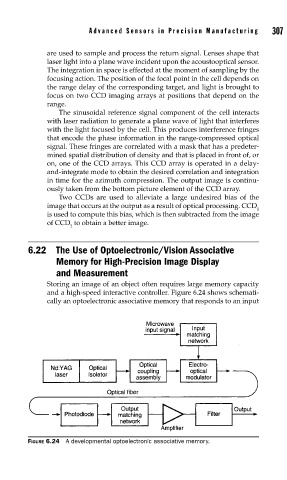

6.22 The Use of Optoelectronic/Vision Associative

Memory for High-Precision Image Display

and Measurement

Storing an image of an object often requires large memory capacity

and a high-speed interactive controller. Figure 6.24 shows schemati-

cally an optoelectronic associative memory that responds to an input

FIGURE 6.24 A developmental optoelectronic associative memory.