Page 354 - Sensors and Control Systems in Manufacturing

P. 354

Advanced Sensors in Pr ecision Manufacturing

6.23 Sensors for Hand-Eye Coordination of Microrobotic 309

Motion Utilizing Vision Technology

The micro motion of a robotic manipulator can be controlled with the

help of dual feedback by a new method that reduces position errors

by an order of magnitude. The errors—typically of the order of

centimeters—are differences between real positions on the one hand

and measured and computed positions on the other; these errors arise

from several sources in the robotic actuators and sensors and in the

kinematic model used in control computations. In comparison with

current manufacturing methods of controlling the motion of a robot

with visual feedback (the robotic equivalent of hand-eye coordina-

tion), the novel method requires neither calibration over the entire

work space nor the use of an absolute reference coordinate frame for

computing transformations between field of view and robot joint

coordinates.

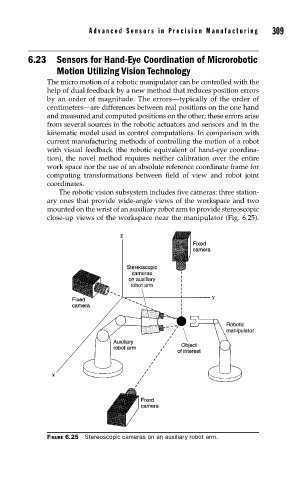

The robotic vision subsystem includes five cameras: three station-

ary ones that provide wide-angle views of the workspace and two

mounted on the wrist of an auxiliary robot arm to provide stereoscopic

close-up views of the workspace near the manipulator (Fig. 6.25).

FIGURE 6.25 Stereoscopic cameras on an auxiliary robot arm.