Page 356 - Sensors and Control Systems in Manufacturing

P. 356

Advanced Sensors in Pr ecision Manufacturing

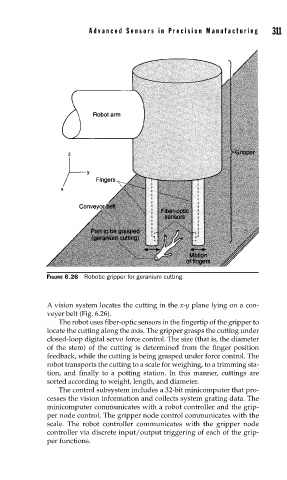

FIGURE 6.26 Robotic gripper for geranium cutting. 311

A vision system locates the cutting in the x-y plane lying on a con-

veyer belt (Fig. 6.26).

The robot uses fiber-optic sensors in the fingertip of the gripper to

locate the cutting along the axis. The gripper grasps the cutting under

closed-loop digital servo force control. The size (that is, the diameter

of the stem) of the cutting is determined from the finger position

feedback, while the cutting is being grasped under force control. The

robot transports the cutting to a scale for weighing, to a trimming sta-

tion, and finally to a potting station. In this manner, cuttings are

sorted according to weight, length, and diameter.

The control subsystem includes a 32-bit minicomputer that pro-

cesses the vision information and collects system grating data. The

minicomputer communicates with a robot controller and the grip-

per node control. The gripper node control communicates with the

scale. The robot controller communicates with the gripper node

controller via discrete input/output triggering of each of the grip-

per functions.