Page 360 - Sensors and Control Systems in Manufacturing

P. 360

Advanced Sensors in Pr ecision Manufacturing

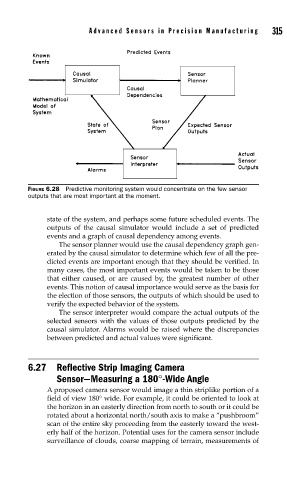

FIGURE 6.28 Predictive monitoring system would concentrate on the few sensor 315

outputs that are most important at the moment.

state of the system, and perhaps some future scheduled events. The

outputs of the causal simulator would include a set of predicted

events and a graph of causal dependency among events.

The sensor planner would use the causal dependency graph gen-

erated by the causal simulator to determine which few of all the pre-

dicted events are important enough that they should be verified. In

many cases, the most important events would be taken to be those

that either caused, or are caused by, the greatest number of other

events. This notion of causal importance would serve as the basis for

the election of those sensors, the outputs of which should be used to

verify the expected behavior of the system.

The sensor interpreter would compare the actual outputs of the

selected sensors with the values of those outputs predicted by the

causal simulator. Alarms would be raised where the discrepancies

between predicted and actual values were significant.

6.27 Reflective Strip Imaging Camera

Sensor—Measuring a 180°-Wide Angle

A proposed camera sensor would image a thin striplike portion of a

field of view 180° wide. For example, it could be oriented to look at

the horizon in an easterly direction from north to south or it could be

rotated about a horizontal north/south axis to make a “pushbroom”

scan of the entire sky proceeding from the easterly toward the west-

erly half of the horizon. Potential uses for the camera sensor include

surveillance of clouds, coarse mapping of terrain, measurements of