Page 358 - Sensors and Control Systems in Manufacturing

P. 358

Advanced Sensors in Pr ecision Manufacturing

involve thermoelasticity and shearography, have been expensive and 313

placed demands on the measured material. The optical measurement

of stress required the application of a phase coat to the object under

test. The laser diffraction method required notching or sharp mark-

ing of the specimen.

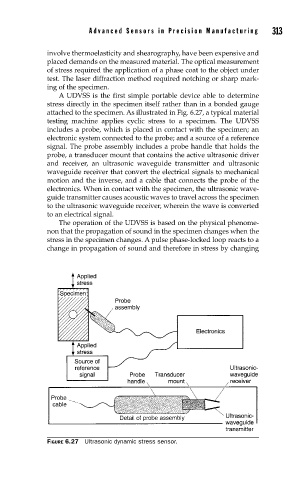

A UDVSS is the first simple portable device able to determine

stress directly in the specimen itself rather than in a bonded gauge

attached to the specimen. As illustrated in Fig. 6.27, a typical material

testing machine applies cyclic stress to a specimen. The UDVSS

includes a probe, which is placed in contact with the specimen; an

electronic system connected to the probe; and a source of a reference

signal. The probe assembly includes a probe handle that holds the

probe, a transducer mount that contains the active ultrasonic driver

and receiver, an ultrasonic waveguide transmitter and ultrasonic

waveguide receiver that convert the electrical signals to mechanical

motion and the inverse, and a cable that connects the probe of the

electronics. When in contact with the specimen, the ultrasonic wave-

guide transmitter causes acoustic waves to travel across the specimen

to the ultrasonic waveguide receiver, wherein the wave is converted

to an electrical signal.

The operation of the UDVSS is based on the physical phenome-

non that the propagation of sound in the specimen changes when the

stress in the specimen changes. A pulse phase-locked loop reacts to a

change in propagation of sound and therefore in stress by changing

FIGURE 6.27 Ultrasonic dynamic stress sensor.