Page 532 - Sensors and Control Systems in Manufacturing

P. 532

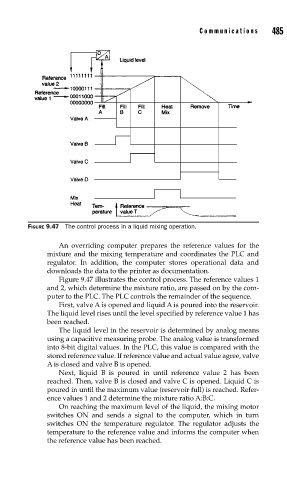

FIGURE 9.47 The control process in a liquid mixing operation. Communications 485

An overriding computer prepares the reference values for the

mixture and the mixing temperature and coordinates the PLC and

regulator. In addition, the computer stores operational data and

downloads the data to the printer as documentation.

Figure 9.47 illustrates the control process. The reference values 1

and 2, which determine the mixture ratio, are passed on by the com-

puter to the PLC. The PLC controls the remainder of the sequence.

First, valve A is opened and liquid A is poured into the reservoir.

The liquid level rises until the level specified by reference value 1 has

been reached.

The liquid level in the reservoir is determined by analog means

using a capacitive measuring probe. The analog value is transformed

into 8-bit digital values. In the PLC, this value is compared with the

stored reference value. If reference value and actual value agree, valve

A is closed and valve B is opened.

Next, liquid B is poured in until reference value 2 has been

reached. Then, valve B is closed and valve C is opened. Liquid C is

poured in until the maximum value (reservoir full) is reached. Refer-

ence values 1 and 2 determine the mixture ratio A:B:C.

On reaching the maximum level of the liquid, the mixing motor

switches ON and sends a signal to the computer, which in turn

switches ON the temperature regulator. The regulator adjusts the

temperature to the reference value and informs the computer when

the reference value has been reached.