Page 37 - Separation process principles 2

P. 37

1.1 Industrial Chemical Processes 5

- Methane-rich gas Ethane

/

*

<

a Demethanizer

Absorber (reboiled

Deethanizer

Wet natural gas

I

r Recycle absorbent I

J

lsobutane

%

Depropanizer

(distillation)

Deisobutanizer

(distillation)

Debutanizer

(distillation)

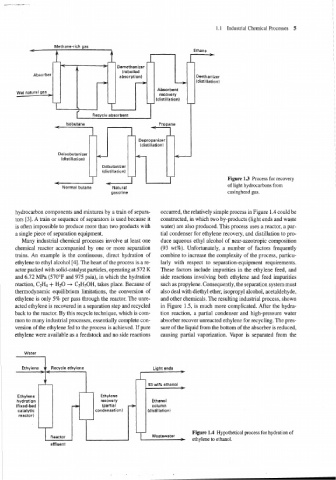

1 - Figure 1.3 Process for recovery

Normal butane Natural of light hydrocarbons from

gasoline casinghead gas.

hydrocarbon components and mixtures by a train of separa- occurred, the relatively simple process in Figure 1.4 could be

tors [3]. A train or sequence of separators is used because it constructed, in which two by-products (light ends and waste

is often impossible to produce more than two products with water) are also produced. This process uses a reactor, a par-

a single piece of separation equipment. tial condenser for ethylene recovery, and distillation to pro-

Many industrial chemical processes involve at least one duce aqueous ethyl alcohol of near-azeotropic composition

chemical reactor accompanied by one or more separation (93 wt%). Unfortunately, a number of factors frequently

trains. An example is the continuous, direct hydration of combine to increase the complexity of the process, particu-

ethylene to ethyl alcohol [4]. The heart of the process is a re- larly with respect to separation-equipment requirements.

actor packed with solid-catalyst particles, operating at 572 K These factors include impurities in the ethylene feed, and

and 6.72 MPa (570°F and 975 psia), in which the hydration side reactions involving both ethylene and feed impurities

reaction, C2H4 + H20 + C2H50H, takes place. Because of such as propylene. Consequently, the separation system must

thermodynamic equilibrium limitations, the conversion of also deal with diethyl ether, isopropyl alcohol, acetaldehyde,

ethylene is only 5% per pass through the reactor. The unre- and other chemicals. The resulting industrial process, shown

acted ethylene is recovered in a separation step and recycled in Figure 1.5, is much more complicated. After the hydra-

back to the reactor. By this recycle technique, which is com- tion reaction, a partial condenser and high-pressure water

mon to many industrial processes, essentially complete con- absorber recover unreacted ethylene for recycling. The pres-

version of the ethylene fed to the process is achieved. If pure sure of the liquid from the bottom of the absorber is reduced,

ethylene were available as a feedstock and no side reactions causing partial vaporization. Vapor is separated from the

Ethylene Recycle ethylene Light ends

<

93 wt% ethanol

-

Ethylene Ethylene

hydration recovery Ethanol

(fixed-bed 3 (partial + column

catalytic condensation) (distillationl

reactor)

Figure 1.4 Hypothetical process for hydration of

Reactor Wastewater

: ethylene to ethanol.

effluent