Page 38 - Separation process principles 2

P. 38

6 Chapter 1 Separation Processes

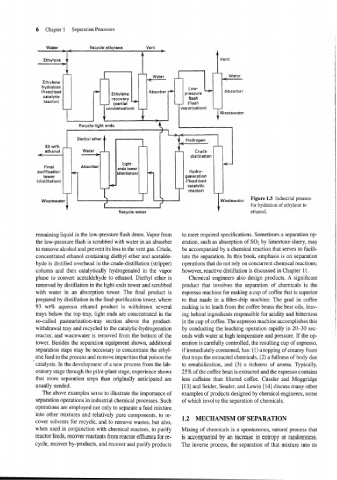

Water Recycle ethylene Vent

Ethylene t vent

Water Water

Ethylene

hydration

(fixed-bed pressure

catalytic

reactor)

astewater Figure 1.5 Industrial process

for hydration of ethylene to

Recycle water ethanol.

remaining liquid in the low-pressure flash drum. Vapor from to meet required specifications. Sometimes a separation op-

the low-pressure flash is scrubbed with water in an absorber eration, such as absorption of SOz by limestone slurry, may

to remove alcohol and prevent its loss to the vent gas. Crude, be accompanied by a chemical reaction that serves to facili-

concentrated ethanol containing diethyl ether and acetalde- tate the separation. In this book, emphasis is on separation

hyde is distilled overhead in the crude-distillation (stripper) operations that do not rely on concurrent chemical reactions;

column and then catalytically hydrogenated in the vapor however, reactive distillation is discussed in Chapter 11.

phase to convert acetaldehyde to ethanol. Diethyl ether is Chemical engineers also design products. A significant

removed by distillation in the light-ends tower and scrubbed product that involves the separation of chemicals is the

with water in an absorption tower. The final product is espresso machine for making a cup of coffee that is superior

prepared by distillation in the final-purification tower, where to that made in a filter-drip machine. The goal in coffee

93 wt% aqueous ethanol product is withdrawn several making is to leach from the coffee beans the best oils, leav-

trays below the top tray, light ends are concentrated in the ing behind ingredients responsible for acidity and bitterness

so-called pasteurization-tray section above the product- in the cup of coffee. The espresso machine accomplishes this

withdrawal tray and recycled to the catalytic-hydrogenation by conducting the leaching operation rapidly in 20-30 sec-

reactor, and wastewater is removed from the bottom of the onds with water at high temperature and pressure. If the op-

tower. Besides the separation equipment shown, additional eration is carefully controlled, the resulting cup of espresso,

separation steps may be necessary to concentrate the ethyl- if immediately consumed, has: (1) a topping of creamy foam

ene feed to the process and remove impurities that poison the that traps the extracted chemicals, (2) a fullness of body due

catalysts. In the development of a new process from the lab- to emulsification, and (3) a richness of aroma. Typically,

oratory stage through the pilot-plant stage, experience shows 25% of the coffee bean is extracted and the espresso contains

that more separation steps than originally anticipated are less caffeine than filtered coffee. Cussler and Moggridge

usually needed. [13] and Seider, Seader, and Lewin [14] discuss many other

The above examples serve to illustrate the importance of examples of products designed by chemical engineers, some

separation operations in industrial chemical processes. Such of which involve the separation of chemicals.

operations are employed not only to separate a feed mixture

into other mixtures and relatively pure components, to re-

1.2 MECHANISM OF SEPARATION

cover solvents for recycle, and to remove wastes, but also,

when used in conjunction with chemical reactors, to purify Mixing of chemicals is a spontaneous, natural process that

reactor feeds, recover reactants from reactor effluents for re- is accompanied by an increase in entropy or randomness.

cycle, recover by-products, and recover and purify products The inverse process, the separation of that mixture into its