Page 39 - Separation process principles 2

P. 39

1.2 Mechanism of Separation 7

Product 1 reduction. A second technique, Figure 1.7b, is to introduce

7

the second phase into the system in the form of a solvent that

Feed mixture

selectively dissolves some of the species in the feed. Less

common, but of growing importance, is the use of a barrier,

Figure 1.7c, which restricts and/or enhances the movement

of certain chemical species with respect to other species.

Also of growing importance are techniques that involve the

Figure 1.6 General separation process.

addition of solid particles, Figure 1.7d, which act directly or

as inert carriers for other substances so as to cause separa-

constituent chemical species, is not a spontaneous process; it tion. Finally, external fields, Figure 1.7e, of various types are

requires an expenditure of energy. A mixture to be separated sometimes applied for specialized separations.

usually originates as a single, homogeneous phase (solid, For all the techniques of Figure 1.7, separations are

liquid, or gas). If it exists as two or more immiscible phases, achieved by enhancing the rate of mass transfer by diffusion

it is often best to first use a mechanical means based on of certain species relative to mass transfer of all species by

gravity, centrifugal force, pressure reduction, or an electric bulk movement within a particular phase. The driving force

and/or magnetic field to separate the phases. Then, appropri- and direction of mass transfer by diffusion is governed by

ate separation techniques are applied to each phase. thermodynamics, with the usual limitations of equilibrium.

A schematic diagram of a general separation process is Thus, both transport and thermodynamic considerations are

shown in Figure 1.6. The feed mixture can be vapor, liquid, crucial in separation operations. The rate of separation is

or solid, while the two or more products may differ in com- governed by mass transfel; while the extent of separation is

position from each other and the feed, and may differ in limited by thermodynamic equilibrium. These two topics are

phase state from each other and/or from the feed. The sepa- treated in Chapters 2, 3, and 4. Fluid mechanics and heat

ration is accomplished by forcing the different chemical transfer also play important roles, and applicable principles

species in the feed into different spatial locations by any of are included in appropriate chapters, particularly with respect

five general separation techniques, or combinations thereof, to phase separation, phase change, pressure drop, tempera-

as shown in Figure 1.7. The most common industrial tech- ture change, and entrainment.

nique, Figure 1.7a, involves the creation of a second phase The extent of separation achieved between or among the

(vapor, liquid, or solid) that is immiscible with the feed product phases for each of the chemical species present

phase. The creation is accomplished by energy (heat andlor in the feed depends on the exploitation of differences in

shaft-work) transfer to or from the process or by pressure molecular, thermodynamic, and transport properties of the

- Phase 2

Feed

Creation

Phase 2

Phase, 1 + MrrA , 1 +

Phase 1

7

Feed Barrier 7

Phase 1

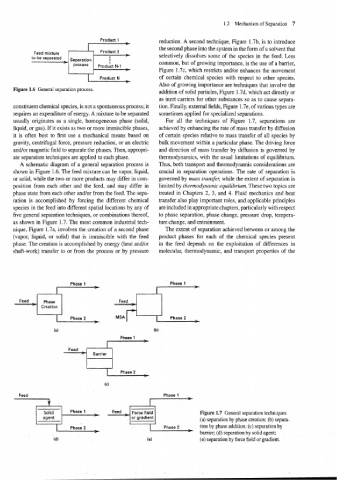

1 , 1 bxl Force fie,; 1 Figure 1.7 General separation techniques:

or gradient

S$itt

phase 1

(a) separation by phase creation; (b) separa-

Phase 2 Phase 2 tion by phase addition; (c) separation by

barrier; (d) separation by solid agent;

(dl (el (e) separation by force field or gradient.