Page 109 - Serious Incident Prevention How to Achieve and Sustain Accident-Free Operations in Your Plant or Company

P. 109

CH08pp083-095 4/10/02 12:50 PM Page 87

Identifying the Critical Work 87

dents include facility inspections, testing of equipment and instrumentation,

development of procedures, training, near-miss and accident investigation,

emergency response drills, and effective management-of-change procedures.

Few of these actions are difficult to achieve singularly, but in total com-

prise a comprehensive system of critical work requiring significant re-

sources and a constancy-of-purpose to effectively manage. An effective

incident-prevention process is needed to facilitate identification and dili-

gent long-term execution of the critical work.

Identifying Critical Work

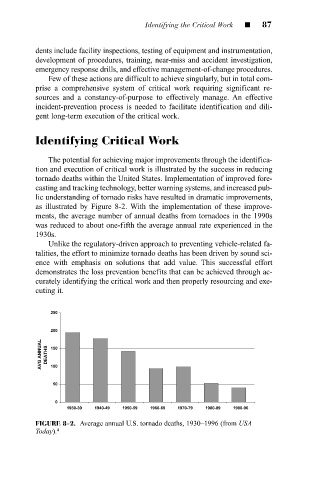

The potential for achieving major improvements through the identifica-

tion and execution of critical work is illustrated by the success in reducing

tornado deaths within the United States. Implementation of improved fore-

casting and tracking technology, better warning systems, and increased pub-

lic understanding of tornado risks have resulted in dramatic improvements,

as illustrated by Figure 8-2. With the implementation of these improve-

ments, the average number of annual deaths from tornadoes in the 1990s

was reduced to about one-fifth the average annual rate experienced in the

1930s.

Unlike the regulatory-driven approach to preventing vehicle-related fa-

talities, the effort to minimize tornado deaths has been driven by sound sci-

ence with emphasis on solutions that add value. This successful effort

demonstrates the loss prevention benefits that can be achieved through ac-

curately identifying the critical work and then properly resourcing and exe-

cuting it.

250

200

AVG ANNUAL DEATHS 150

100

50

0

1930-39 1940-49 1950-59 1960-69 1970-79 1980-89 1990-96

FIGURE 8-2. Average annual U.S. tornado deaths, 1930–1996 (from USA

Today). 4