Page 186 - Serious Incident Prevention How to Achieve and Sustain Accident-Free Operations in Your Plant or Company

P. 186

CH14pp153-158 4/10/02 12:51 PM Page 155

Improving and Updating the Process 155

Shared Vision

A shared vision serves as a beacon highlighting the direction in which

to head when various organizational priorities appear to be in tension with

one another. Great accomplishments, dependent upon the combined efforts

of individuals, have always involved commitment to a common objective. A

successful moon landing, winning a war, a sports triumph, achievement of

an improved safety culture—all require a shared vision.

Many managers confuse mere compliance with thier organization’s vi-

sion to the real need for commitment to the vision. Individuals who are

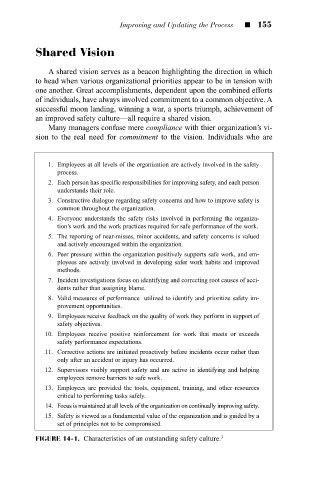

1. Employees at all levels of the organization are actively involved in the safety

process.

2. Each person has specific responsibilities for improving safety, and each person

understands their role.

3. Constructive dialogue regarding safety concerns and how to improve safety is

common throughout the organization.

4. Everyone understands the safety risks involved in performing the organiza-

tion’s work and the work practices required for safe performance of the work.

5. The reporting of near-misses, minor accidents, and safety concerns is valued

and actively encouraged within the organization.

6. Peer pressure within the organization positively supports safe work, and em-

ployees are actively involved in developing safer work habits and improved

methods.

7. Incident investigations focus on identifying and correcting root causes of acci-

dents rather than assigning blame.

8. Valid measures of performance utilized to identify and prioritize safety im-

provement opportunities.

9. Employees receive feedback on the quality of work they perform in support of

safety objectives.

10. Employees receive positive reinforcement for work that meets or exceeds

safety performance expectations.

11. Corrective actions are initiated proactively before incidents occur rather than

only after an accident or injury has occurred.

12. Supervisors visibly support safety and are active in identifying and helping

employees remove barriers to safe work.

13. Employees are provided the tools, equipment, training, and other resources

critical to performing tasks safely.

14. Focus is maintained at all levels of the organization on continually improving safety.

15. Safety is viewed as a fundamental value of the organization and is guided by a

set of principles not to be compromised.

FIGURE 14-1. Characteristics of an outstanding safety culture. 3