Page 58 - Serious Incident Prevention How to Achieve and Sustain Accident-Free Operations in Your Plant or Company

P. 58

CH03pp029-036 4/10/02 12:49 PM Page 36

36 Serious Incident Prevention

Management Commitment

and Leadership

Involve Employees

Understand the Risks

Identify Critical Work for

Controlling the Risks

Establish Performance

Standards

Maintain Measurement and

Feedback Systems

Reinforce and Implement

Corrective Action

Improve and Update the

Process

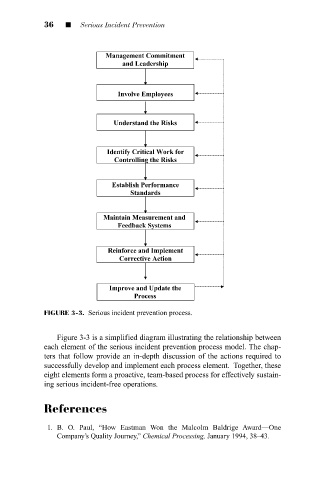

FIGURE 3-3. Serious incident prevention process.

Figure 3-3 is a simplified diagram illustrating the relationship between

each element of the serious incident prevention process model. The chap-

ters that follow provide an in-depth discussion of the actions required to

successfully develop and implement each process element. Together, these

eight elements form a proactive, team-based process for effectively sustain-

ing serious incident-free operations.

References

1. B. O. Paul, “How Eastman Won the Malcolm Baldrige Award—One

Company’s Quality Journey,” Chemical Processing, January 1994, 38–43.