Page 97 - Serious Incident Prevention How to Achieve and Sustain Accident-Free Operations in Your Plant or Company

P. 97

CH07pp068-82 4/10/02 12:50 PM Page 75

Understanding the Risks 75

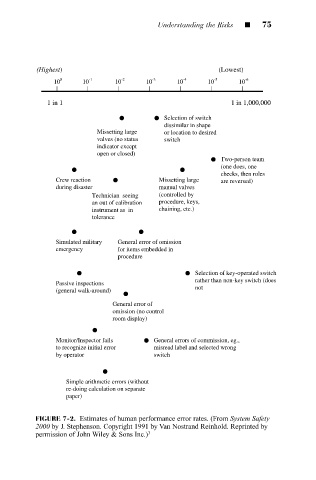

(Highest) (Lowest)

10 0 10 -1 10 -2 10 -3 10 -4 10 -5 10 -6

1 in 1 1 in 1,000,000

• • Selection of switch

dissimilar in shape

Missetting large or location to desired

valves (no status switch

indicator except

open or closed) • Two-person team

• • (one does, one

Crew reaction • Missetting large checks, then roles

are reversed)

during disaster manual valves

Technician seeing (controlled by

an out of calibration procedure, keys,

instrument as in chaining, etc.)

tolerance

• •

Simulated military General error of omission

emergency for items embedded in

procedure

• • Selection of key-operated switch

rather than non-key switch (does

Passive inspections

•

(general walk-around) not

General error of

omission (no control

room display)

•

Monitor/Inspector fails • General errors of commission, eg.,

to recognize initial error misread label and selected wrong

by operator switch

•

Simple arithmetic errors (without

re-doing calculation on separate

paper)

FIGURE 7-2. Estimates of human performance error rates. (From System Safety

2000 by J. Stephenson. Copyright 1991 by Van Nostrand Reinhold. Reprinted by

permission of John Wiley & Sons Inc.) 3