Page 132 - Shale Shakers Drilling Fluid Systems

P. 132

CHAPTE R FIV E

Shaker User's Guide

All solids removal systems should have enough

shale shakers to process 100% of the drilling fluid

circulating rate. For expensive wells, an evaluation

should be conducted to determine the drilling fluid

processing system needed to minimize drilling

and disposal costs. On the basis of this evaluation,

the number, type, and configuration of shaker(s)

can be chosen (see Selecting Shaker Screens dis-

cussed in Chapter 4). The following guidelines FIGURE 5-1

address the installation, operation, and mainte-

nance of shale shakers.

INSTALLATION

In all cases, the owner's manual should be

consulted for proper installation procedures. If

unavailable, the general guidelines below may

be helpful: FIGURE 5-2

1. Low places in the flow line will trap cuttings.

The flow-line angle should be such that sol-

ids settling does not occur. In general, estab-

lish a 1-inch drop for every 10 feet of flow line.

2. When using a back tank, also known as a

possum belly, the flow line should enter the

bottom to prevent solids from settling and

accumulating. If the flow line enters the top

of the back tank, it should be extended to

within one pipe diameter of the flow line FIGURE 5-3

from the bottom.

3. Rig up with sufficient space and approved

walkways around the shaker(s) to permit

easy maintenance. An optional top delivery (Figure 5-3) prevents

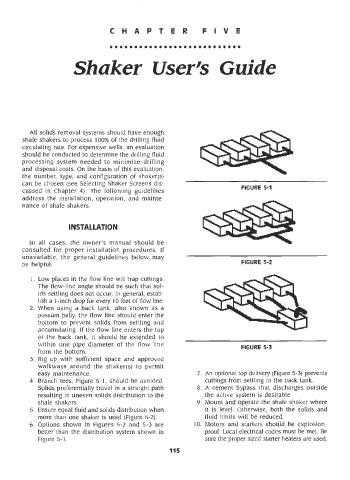

4. Branch tees, Figure 5-1, should be avoided. cuttings from settling in the back tank.

Solids preferentially travel in a straight path A cement bypass that discharges outside

resulting in uneven solids distribution to the the active system is desirable.

shale shakers. Mount and operate the shale shaker where

5. Ensure equal fluid and solids distribution when it is level. Otherwise, both the solids and

more than one shaker is used (Figure 5-2). fluid limits will be reduced.

6. Options shown in Figures 5-2 and 5-3 are 10. Motors and starters should be explosion-

better than the distribution system shown in proof. Local electrical codes must be met. Be

Figure 5-1. sure the proper sized starter heaters are used.

115