Page 182 - Shale Shakers Drilling Fluid Systems

P. 182

DILUTION 165

3. The removal efficiency of the solids con- removal equipment determines the quantity of

trol arrangement can vary significantly de- drilling fluid that must be built to maintain a tar-

pending on the adherence to sound arrange- geted drilled-solids concentration and a constant

ment practices and operating conditions. Many pit volume. These representative calculations

drilling rigs with poor solids management describe the fate and effect of 100 barrels of drilled

have trouble reducing the mud weight below solids arriving at the surface. (Note, this may

9.7 ppg. While others can comfortably create not correspond to generating 100 bbl of borehole

an 8.8 ppg drilling fluid. This is related to the because of lag time and solids storage in the well-

removal efficiency. API RP13C provides a bore.) The first set of calculations is based on a

new method of following a tracer to deter- solids removal section that is removing 100%, 90%,

mine the solids removal efficiency. In the or 80% by volume of the drilled solids, with the

following section, a second method is targeted drilled solids level set at 4% volume. For

presented. These methods can be used this comparison, assume 100 bbl is approximately

while drilling a reasonably deep hole (such the volume of 1,000 feet of a 10-inch diameter

as 1,000 to 2,000 feet). The analysis assumes hole. This analysis is the basis for calculating the

that no drilling fluid is jetted from the sys- minimum desirable removal efficiency. It also shows

tern. The removal efficiency of the system in the minimum quantity of new drilling fluid and

an unweighted drilling fluid is usually higher minimizes the volume of discarded fluid. These

than in a weighted drilling fluid. Solids in the calculations assume no migration of fluid to or

same size range as the weighting material from the wellbore, no rock compressibility, and no

cannot be removed with known technology. gas migration to the surface. These example cal-

culations also assume that the removed drilled

solids concentration is 35% by volume.

In the case of 100% removal efficiency, all

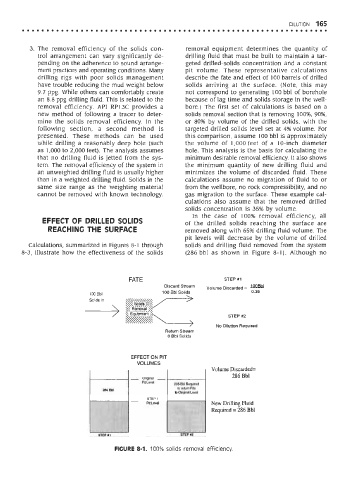

EFFECT OF DRILLED SOLIDS of the drilled solids reaching the surface are

REACHING THE SURFACE removed along with 65% drilling fluid volume. The

pit levels will decrease by the volume of drilled

Calculations, summarized in Figures 8-1 through solids and drilling fluid removed from the system

8-3, illustrate how the effectiveness of the solids (286 bbl as shown in Figure 8-1). Although no

FIGURE 8-1. 100% solids removal efficiency.