Page 253 - Shale Shakers Drilling Fluid Systems

P. 253

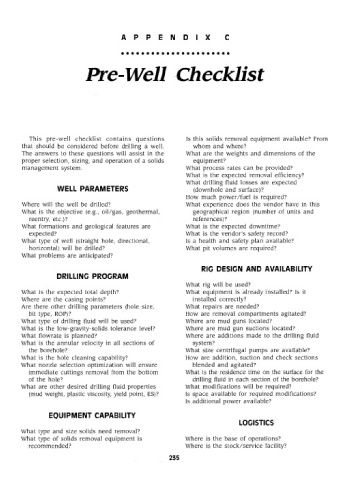

APPENDI X C

Pre-Well Checklist

This pre-well checklist contains questions Is this solids removal equipment available? From

that should be considered before drilling a well. whom and where?

The answers to these questions will assist in the What are the weights and dimensions of the

proper selection, sizing, and operation of a solids equipment?

management system. What process rates can be provided?

What is the expected removal efficiency?

What drilling fluid losses are expected

WELL PARAMETERS (downhole and surface)?

How much power/fuel is required?

Where will the well be drilled? What experience does the vendor have in this

What is the objective (e.g., oil/gas, geothermal, geographical region (number of units and

reentry, etc.)? references)?

What formations and geological features are What is the expected downtime?

expected? What is the vendor's safety record?

What type of well (straight hole, directional, Is a health and safety plan available?

horizontal) will be drilled? What pit volumes are required?

What problems are anticipated?

RIG DESIGN AND AVAILABILITY

DRILLING PROGRAM

What rig will be used?

What is the expected total depth? What equipment is already installed? Is it

Where are the casing points? installed correctly?

Are there other drilling parameters (hole size, What repairs are needed?

bit type, ROP)? How are removal compartments agitated?

What type of drilling fluid will be used? Where are mud guns located?

What is the low-gravity-solids tolerance level? Where are mud gun suctions located?

What flowrate is planned? Where are additions made to the drilling fluid

What is the annular velocity in all sections of system?

the borehole? What size centrifugal pumps are available?

What is the hole cleaning capability? How are addition, suction and check sections

What nozzle selection optimization will ensure blended and agitated?

immediate cuttings removal from the bottom What is the residence time on the surface for the

of the hole? drilling fluid in each section of the borehole?

What are other desired drilling fluid properties What modifications will be required?

(mud weight, plastic viscosity, yield point, ES)? Is space available for required modifications?

Is additional power available?

EQUIPMENT CAPABILITY

LOGISTICS

What type and size solids need removal?

What type of solids removal equipment is Where is the base of operations?

recommended? Where is the stock/service facility?

235