Page 15 - Shigley's Mechanical Engineering Design

P. 15

bud29281_fm_i-xxii_1.qxd 12/24/09 3:38 PM Page xii epg Disk1:Desktop Folder:TEMPWORK:Don't-Delete Jobs:MHDQ196/Budynas:

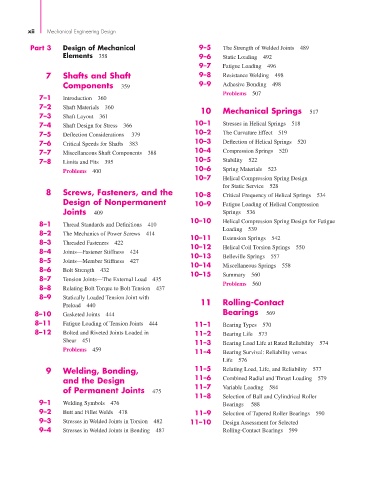

xii Mechanical Engineering Design

Part 3 Design of Mechanical 9–5 The Strength of Welded Joints 489

Elements 358 9–6 Static Loading 492

9–7 Fatigue Loading 496

7 Shafts and Shaft 9–8 Resistance Welding 498

Components 359 9–9 Adhesive Bonding 498

Problems 507

7–1 Introduction 360

7–2 Shaft Materials 360 10 Mechanical Springs

7–3 Shaft Layout 361 517

7–4 Shaft Design for Stress 366 10–1 Stresses in Helical Springs 518

7–5 Deflection Considerations 379 10–2 The Curvature Effect 519

7–6 Critical Speeds for Shafts 383 10–3 Deflection of Helical Springs 520

7–7 Miscellaneous Shaft Components 388 10–4 Compression Springs 520

7–8 Limits and Fits 395 10–5 Stability 522

10–6 Spring Materials 523

Problems 400

10–7 Helical Compression Spring Design

for Static Service 528

8 Screws, Fasteners, and the 10–8 Critical Frequency of Helical Springs 534

Design of Nonpermanent 10–9 Fatigue Loading of Helical Compression

Joints 409 Springs 536

10–10 Helical Compression Spring Design for Fatigue

8–1 Thread Standards and Definitions 410

Loading 539

8–2 The Mechanics of Power Screws 414

10–11 Extension Springs 542

8–3 Threaded Fasteners 422

10–12 Helical Coil Torsion Springs 550

8–4 Joints—Fastener Stiffness 424

10–13 Belleville Springs 557

8–5 Joints—Member Stiffness 427

10–14 Miscellaneous Springs 558

8–6 Bolt Strength 432

10–15 Summary 560

8–7 Tension Joints—The External Load 435

Problems 560

8–8 Relating Bolt Torque to Bolt Tension 437

8–9 Statically Loaded Tension Joint with

Preload 440 11 Rolling-Contact

8–10 Gasketed Joints 444 Bearings 569

8–11 Fatigue Loading of Tension Joints 444 11–1 Bearing Types 570

8–12 Bolted and Riveted Joints Loaded in 11–2 Bearing Life 573

Shear 451 11–3 Bearing Load Life at Rated Reliability 574

Problems 459 11–4 Bearing Survival: Reliability versus

Life 576

9 Welding, Bonding, 11–5 Relating Load, Life, and Reliability 577

and the Design 11–6 Combined Radial and Thrust Loading 579

of Permanent Joints 475 11–7 Variable Loading 584

11–8 Selection of Ball and Cylindrical Roller

9–1 Welding Symbols 476 Bearings 588

9–2 Butt and Fillet Welds 478 11–9 Selection of Tapered Roller Bearings 590

9–3 Stresses in Welded Joints in Torsion 482 11–10 Design Assessment for Selected

9–4 Stresses in Welded Joints in Bending 487 Rolling-Contact Bearings 599