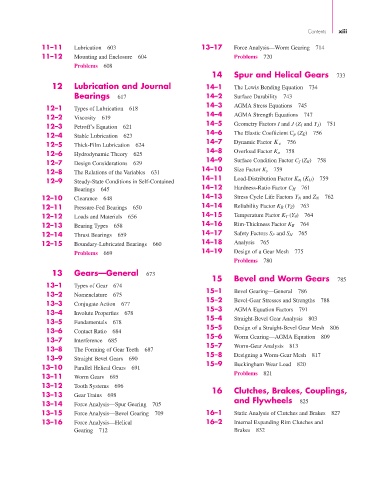

Page 16 - Shigley's Mechanical Engineering Design

P. 16

bud29281_fm_i-xxii_1.qxd 12/24/09 3:38 PM Page xiii epg Disk1:Desktop Folder:TEMPWORK:Don't-Delete Jobs:MHDQ196/Budynas:

Contents xiii

11–11 Lubrication 603 13–17 Force Analysis—Worm Gearing 714

11–12 Mounting and Enclosure 604 Problems 720

Problems 608

14 Spur and Helical Gears 733

12 Lubrication and Journal 14–1 The Lewis Bending Equation 734

Bearings 617 14–2 Surface Durability 743

14–3 AGMA Stress Equations 745

12–1 Types of Lubrication 618

14–4 AGMA Strength Equations 747

12–2 Viscosity 619

14–5 Geometry Factors I and J (Z I and Y J ) 751

12–3 Petroff’s Equation 621

14–6 The Elastic Coefficient C p (Z E ) 756

12–4 Stable Lubrication 623

14–7 756

12–5 Thick-Film Lubrication 624 Dynamic Factor K v

14–8 758

12–6 Hydrodynamic Theory 625 Overload Factor K o

14–9 Surface Condition Factor C f (Z R ) 758

12–7 Design Considerations 629

14–10 759

12–8 The Relations of the Variables 631 Size Factor K s

14–11 Load-Distribution Factor K m (K H ) 759

12–9 Steady-State Conditions in Self-Contained

14–12 761

Bearings 645 Hardness-Ratio Factor C H

12–10 Clearance 648 14–13 Stress Cycle Life Factors Y N and Z N 762

12–11 Pressure-Fed Bearings 650 14–14 Reliability Factor K R (Y Z ) 763

12–12 Loads and Materials 656 14–15 Temperature Factor K T (Y θ ) 764

12–13 Bearing Types 658 14–16 Rim-Thickness Factor K B 764

12–14 Thrust Bearings 659 14–17 Safety Factors S F and S H 765

12–15 Boundary-Lubricated Bearings 660 14–18 Analysis 765

Problems 669 14–19 Design of a Gear Mesh 775

Problems 780

13 Gears—General 673

15 Bevel and Worm Gears 785

13–1 Types of Gear 674

15–1 Bevel Gearing—General 786

13–2 Nomenclature 675

15–2 Bevel-Gear Stresses and Strengths 788

13–3 Conjugate Action 677

15–3 AGMA Equation Factors 791

13–4 Involute Properties 678

15–4 Straight-Bevel Gear Analysis 803

13–5 Fundamentals 678

15–5 Design of a Straight-Bevel Gear Mesh 806

13–6 Contact Ratio 684

15–6 Worm Gearing—AGMA Equation 809

13–7 Interference 685

15–7 Worm-Gear Analysis 813

13–8 The Forming of Gear Teeth 687

15–8 Designing a Worm-Gear Mesh 817

13–9 Straight Bevel Gears 690

15–9 Buckingham Wear Load 820

13–10 Parallel Helical Gears 691

Problems 821

13–11 Worm Gears 695

13–12 Tooth Systems 696 16 Clutches, Brakes, Couplings,

13–13 Gear Trains 698

13–14 Force Analysis—Spur Gearing 705 and Flywheels 825

13–15 Force Analysis—Bevel Gearing 709 16–1 Static Analysis of Clutches and Brakes 827

13–16 Force Analysis—Helical 16–2 Internal Expanding Rim Clutches and

Gearing 712 Brakes 832