Page 190 - Six Sigma Demystified

P. 190

170 Six SigMa DemystifieD

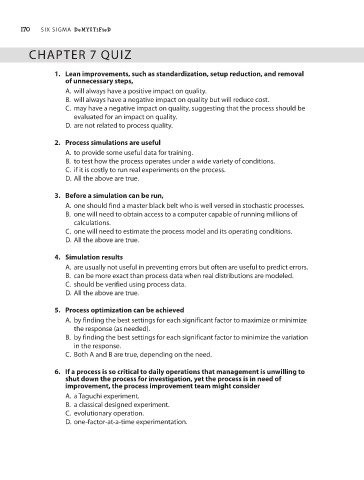

CHaPTER 7 QUiz

1. Lean improvements, such as standardization, setup reduction, and removal

of unnecessary steps,

a. will always have a positive impact on quality.

B. will always have a negative impact on quality but will reduce cost.

C. may have a negative impact on quality, suggesting that the process should be

evaluated for an impact on quality.

D. are not related to process quality.

2. Process simulations are useful

a. to provide some useful data for training.

B. to test how the process operates under a wide variety of conditions.

C. if it is costly to run real experiments on the process.

D. all the above are true.

3. Before a simulation can be run,

a. one should find a master black belt who is well versed in stochastic processes.

B. one will need to obtain access to a computer capable of running millions of

calculations.

C. one will need to estimate the process model and its operating conditions.

D. all the above are true.

4. Simulation results

a. are usually not useful in preventing errors but often are useful to predict errors.

B. can be more exact than process data when real distributions are modeled.

C. should be verified using process data.

D. all the above are true.

5. Process optimization can be achieved

a. by finding the best settings for each significant factor to maximize or minimize

the response (as needed).

B. by finding the best settings for each significant factor to minimize the variation

in the response.

C. Both a and B are true, depending on the need.

6. If a process is so critical to daily operations that management is unwilling to

shut down the process for investigation, yet the process is in need of

improvement, the process improvement team might consider

a. a Taguchi experiment.

B. a classical designed experiment.

C. evolutionary operation.

D. one- factor- at- a- time experimentation.