Page 442 - Six Sigma Demystified

P. 442

422 Six SigMa DemystifieD

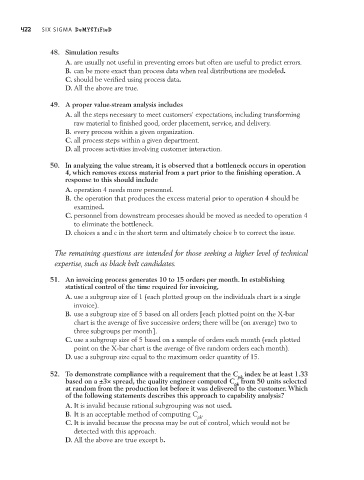

48. Simulation results

A. are usually not useful in preventing errors but often are useful to predict errors.

b. can be more exact than process data when real distributions are modeled.

c. should be verified using process data.

d. All the above are true.

49. A proper value-stream analysis includes

A. all the steps necessary to meet customers’ expectations, including transforming

raw material to finished good, order placement, service, and delivery.

b. every process within a given organization.

c. all process steps within a given department.

d. all process activities involving customer interaction.

50. In analyzing the value stream, it is observed that a bottleneck occurs in operation

4, which removes excess material from a part prior to the finishing operation. A

response to this should include

A. operation 4 needs more personnel.

b. the operation that produces the excess material prior to operation 4 should be

examined.

c. personnel from downstream processes should be moved as needed to operation 4

to eliminate the bottleneck.

d. choices a and c in the short term and ultimately choice b to correct the issue.

The remaining questions are intended for those seeking a higher level of technical

expertise, such as black belt candidates.

51. An invoicing process generates 10 to 15 orders per month. In establishing

statistical control of the time required for invoicing,

A. use a subgroup size of 1 (each plotted group on the individuals chart is a single

invoice).

b. use a subgroup size of 5 based on all orders [each plotted point on the X-bar

chart is the average of five successive orders; there will be (on average) two to

three subgroups per month].

c. use a subgroup size of 5 based on a sample of orders each month (each plotted

point on the X-bar chart is the average of five random orders each month).

d. use a subgroup size equal to the maximum order quantity of 15.

52. To demonstrate compliance with a requirement that the C index be at least 1.33

pk

based on a ±3× spread, the quality engineer computed C from 50 units selected

pk

at random from the production lot before it was delivered to the customer. Which

of the following statements describes this approach to capability analysis?

A. It is invalid because rational subgrouping was not used.

b. It is an acceptable method of computing C .

pk

c. It is invalid because the process may be out of control, which would not be

detected with this approach.

d. All the above are true except b.