Page 48 - Six Sigma for electronics design and manufacturing

P. 48

Six Sigma for Electronics Design and Manufacturing

18

DFM analysis results in reduced production time and need for oper-

ator skills. The DFM design guidelines, such as the ones mentioned

above, are based on common lessons learned while developing elec-

tronic products. Prior to formal DFM systems, checklists were being

used by major electronic companies as a repository for the collective

wisdom of their successful design engineers.

DFM design guidelines emphasize the design of electronic products

using self-locating and self-aligning parts, built on a suitable base

part. The number of parts should be minimized by using standard

parts and integrating functionality and utility. Several cost saving

techniques should be used, such as standard and automatic labeling,

self-diagnosis capability at the lowest level, and using symmetrical

and tangle-free part designs.

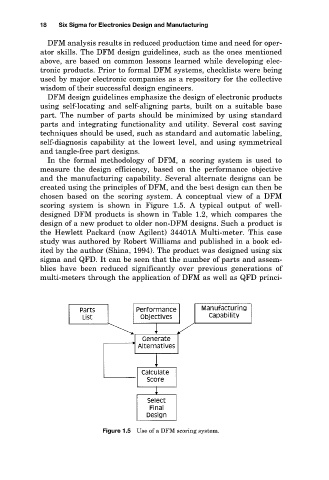

In the formal methodology of DFM, a scoring system is used to

measure the design efficiency, based on the performance objective

and the manufacturing capability. Several alternate designs can be

created using the principles of DFM, and the best design can then be

chosen based on the scoring system. A conceptual view of a DFM

scoring system is shown in Figure 1.5. A typical output of well-

designed DFM products is shown in Table 1.2, which compares the

design of a new product to older non-DFM designs. Such a product is

the Hewlett Packard (now Agilent) 34401A Multi-meter. This case

study was authored by Robert Williams and published in a book ed-

ited by the author (Shina, 1994). The product was designed using six

sigma and QFD. It can be seen that the number of parts and assem-

blies have been reduced significantly over previous generations of

multi-meters through the application of DFM as well as QFD princi-

Figure 1.5 Use of a DFM scoring system.