Page 54 - Six Sigma for electronics design and manufacturing

P. 54

Six Sigma for Electronics Design and Manufacturing

24

2. Establish a set of rules and guidelines.

Work the plan: Do not expedite from the next production period

and do not start more parts than scheduled.

Do not start a job before materials are scheduled or physically

in-house.

Identify and follow schedule control points or whiteboards.

Reduce inventory by developing flexible catch-up plans.

Schedule all whiteboards on the floor at the same time.

3. Goals of the scheduling system using whiteboards:

Visibility and communication of the plan

Track performance to plan

Prioritize jobs

Recovery plan from problems

Improve work flow

Communications with upstream and downstream processes

Production associates assume responsibility to execute the plan

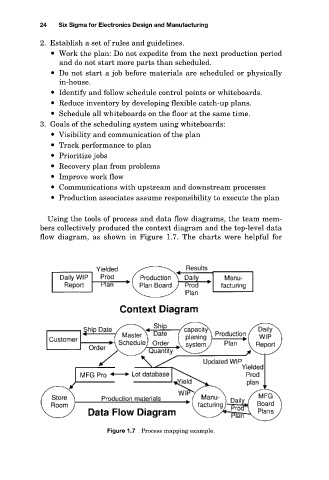

Using the tools of process and data flow diagrams, the team mem-

bers collectively produced the context diagram and the top-level data

flow diagram, as shown in Figure 1.7. The charts were helpful for

Figure 1.7 Process mapping example.