Page 107 - Software and Systems Requirements Engineering in Practice

P. 107

76 S o f t w a r e & S y s t e m s R e q u i r e m e n t s E n g i n e e r i n g : I n P r a c t i c e

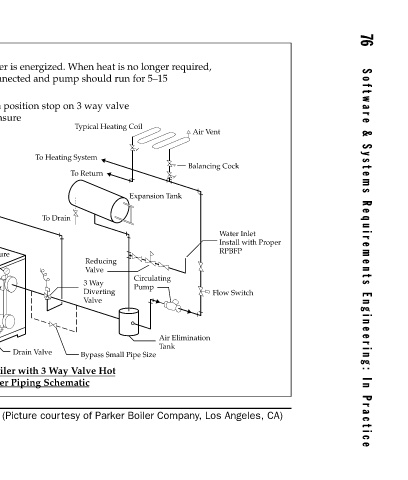

Air Vent Balancing Cock Water Inlet Install with Proper RPBFP Flow Switch Air Elimination

(1) System pump should run at all times boiler is energized. When heat is no longer required,

Expansion Tank Circulating Pump Tank

electrical power to boiler should be disconnected and pump should run for 5–15

Typical Heating Coil To Return Reducing Valve 3 Way Diverting Valve Bypass Small Pipe Size

To Heating System To Drain Temp.- Pressure Drain Valve Single Boiler with 3 Way Valve Hot Water Piping Schematic Conceptual diagram in mechanical engineering (Picture courtesy of Parker Boiler Company, Los Angeles, CA)

minutes before being turned off. (2) When 3 way valve is utilized, a minimum position stop on 3 way valve or an open bypass should be utilized to insure a small flow thru boiler. Heating System Boiler Relief Valve Gauge Electrical Control Panel Operating Control

Note: Return from Inlet to Boiler

Used on Parker Hot Water System Part Name Boiler Piping Schematic

For Direct Fired, Closed System Heating with 3 Way Valve

Dr. RPC Date 11/16/01 PARKER BOILER co. Scale None

Ch. 5930 BANDINI BLVD. Supercedes No. 3-29-96 FIGURE 4.1

Approved LOS ANGELES, CALIF. 90040 DWG. No. A201-INST3