Page 131 - Solid Waste Analysis and Minimization a Systems Approach

P. 131

SUMMARY 109

Pin diameter Check Sheet

Sheet No:

Date: Operator:

Lathe number: Remarks:

Cutter type:

Lower spec. Limit Upper spec. Limit

1.01.11.21.31.41.51.61.71.81.92.02.12.22.32.42.52.62.72.82.93.03.13.23.33.4

25

20

15

10

5

0

Total: 00 0 1 0 1 2 4 7 1014 18 1915 13 9 5 4 2 2 1 00 1 0

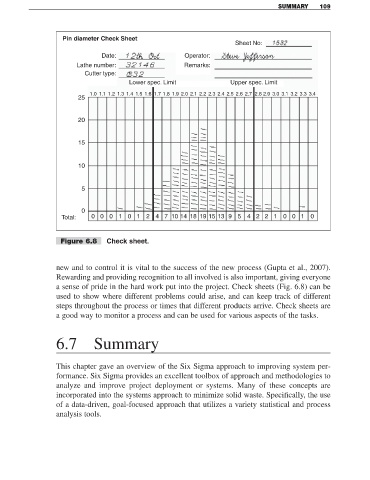

Figure 6.8 Check sheet.

new and to control it is vital to the success of the new process (Gupta et al., 2007).

Rewarding and providing recognition to all involved is also important, giving everyone

a sense of pride in the hard work put into the project. Check sheets (Fig. 6.8) can be

used to show where different problems could arise, and can keep track of different

steps throughout the process or times that different products arrive. Check sheets are

a good way to monitor a process and can be used for various aspects of the tasks.

6.7 Summary

This chapter gave an overview of the Six Sigma approach to improving system per-

formance. Six Sigma provides an excellent toolbox of approach and methodologies to

analyze and improve project deployment or systems. Many of these concepts are

incorporated into the systems approach to minimize solid waste. Specifically, the use

of a data-driven, goal-focused approach that utilizes a variety statistical and process

analysis tools.