Page 385 - Solid Waste Analysis and Minimization a Systems Approach

P. 385

26

APPAREL- AND FABRIC-

MANUFACTURING APPLICATIONS

26.1 Industry Overview

NAICS code: all 31500s

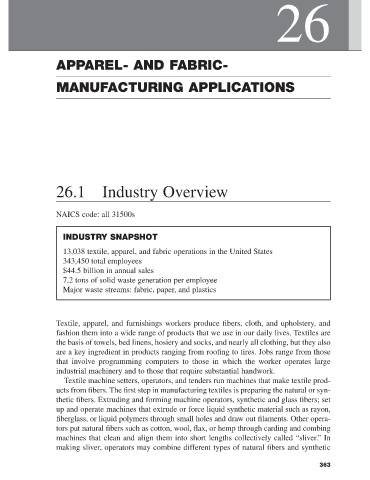

INDUSTRY SNAPSHOT

13,038 textile, apparel, and fabric operations in the United States

343,450 total employees

$44.5 billion in annual sales

7.2 tons of solid waste generation per employee

Major waste streams: fabric, paper, and plastics

Textile, apparel, and furnishings workers produce fibers, cloth, and upholstery, and

fashion them into a wide range of products that we use in our daily lives. Textiles are

the basis of towels, bed linens, hosiery and socks, and nearly all clothing, but they also

are a key ingredient in products ranging from roofing to tires. Jobs range from those

that involve programming computers to those in which the worker operates large

industrial machinery and to those that require substantial handwork.

Textile machine setters, operators, and tenders run machines that make textile prod-

ucts from fibers. The first step in manufacturing textiles is preparing the natural or syn-

thetic fibers. Extruding and forming machine operators, synthetic and glass fibers; set

up and operate machines that extrude or force liquid synthetic material such as rayon,

fiberglass, or liquid polymers through small holes and draw out filaments. Other opera-

tors put natural fibers such as cotton, wool, flax, or hemp through carding and combing

machines that clean and align them into short lengths collectively called “sliver.” In

making sliver, operators may combine different types of natural fibers and synthetic

363