Page 233 - Standard Handbook Of Petroleum & Natural Gas Engineering

P. 233

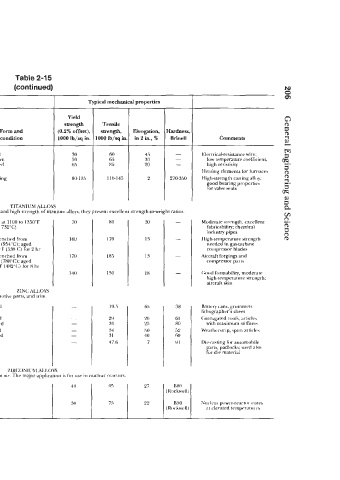

Table 2-1 5

(continued)

Typical mechanical properties

inzin., % 1 Brinell 1

Yield

shengh Tensile ELongation, Hardness,

Nominal

92 1 -

No. Material composition Form and (0.2% offset), shength, Comments

1000 Ib/sq in. 1000 lb/sq in

condition

Cupronirkrl55-45

30

low temperature coefficient,

65

(:"Iddraw"

50

(Constantan) Cu 55.0 Ni 45.0 Annealed 30 60 45 - Electrical-resisuncr wire:

-

Cold-rolled 65 85 20 high resistivity

Ni 80.0 CT 20.0 Heating elements for turnares

NI M).O Cu 290 Sandimting 8C-115 11@145 2 270-350 Highstrength casting ally;

Fe 2.50 Mn 1.5 good bearing properlira

for valw sea5

max max

9 4.0 AI 0.5

max I

TITANIUM ALLOYS

The main applicatiun for thew alloys IS in the aerospace industly Because of the low density and high Wcngrh of utanium alloys. they prebmt e~~ellcni strength-toweight ratios

1

fabricabdity: chemical

ASTM B265-5XT Annealedat 1100 to 1350°F XI) 20 Moderate strength, excellent

(593 to 732°C)

indusiry pipes

[ Waier uenched from I70 13 High-tern erdturr aucngth

ASTM B265 58T 5 1753, (954°C); aged needelw gasturbme

Ti 6 AI 4V at 1000 F 15% C) fur 2 hr compressor hladcs

97 Titanium alloy Waterguenched from 185 13 Aircraft forgings and

Ti 4 AI 4Mn 1450 F (7XX"C). aged compressor parts

at 900°F (48'2°C) fur 8 hr

98 Ti Mnalloy Fe 0.5 Ti bal. Sheet 150 1X Good formability, moderate

ASTM Be65 5RT 7 Mn 7.0 8.0 high-irmprrature Wength.

aircraft skin

99 Zinc Cd 0.35 Zn ha1 I lot-rolled 19.5 65 Baitcry cans, grommets

ASTM B69 Pb 0.08 lithographer's shee1

I00 zlll"y-15 Cu I 00 Zn hal. Hot-rolled 29 20 Corrugated mots, at ticlca

M~ n.010 Cold-rolled 36 25 with maximum sttNnrs*

101 ziiiOy 40 (:I, 1.00 7nhal. Hot-rc,llrd 24 50 Wrathentrip, ~prm drti~lrs

Cold-rolled 'II 40

102 Zamac-5 Zn (YY.99% AI 3.5- Dir-cnst 47 6 7 Dirqasting for automobile

ASTM 25 pure re- 4.3 am, padlock,; rracd also

mainder) Cu 11.75 !or die material

Mg 0.0% 125

0.ox

27

22