Page 241 - Standard Handbook Petroleum Natural Gas Engineering VOLUME2

P. 241

410 Reservoir Engineering

Productivlty Index

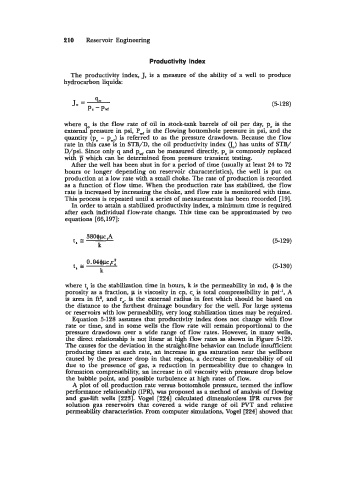

The productivity index, J, is a measure of the ability of a well to produce

hydrocarbon liquids:

9.

J, =- (5-128)

P. - Pllf

where is the flow rate of oil in stock-tank barrels of oil per day, p, is the

external pressure in psi, Pw, is the flowing bottomhole pressure in psi, and the

quantity (p, - p,) is referred to as the pressure drawdown. Because the flow

rate in this case is in STB/D, the oil productivity index u,) has units of STB/

D/psi. Since only q and pwr can be measured directly, p, is commonly replaced

with which can be determined from pressure transient testing.

After the well has been shut in for a period of time (usually at least 24 to 72

hours or longer depending on reservoir characteristics), the well is put on

production at a low rate with a small choke. The rate of production is recorded

as a function of flow time. When the production rate has stabilized, the flow

rate is increased by increasing the choke, and flaw rate is monitored with time.

This process is repeated until a series of measurements has been recorded [19].

In order to attain a stabilized productivity index, a minimum time is required

after each individual flow-rate change. This time can be approximated by two

equations [66,197]:

(5-129)

(5-1 30)

where t, is the stabilization time in hours, k is the permeability in md, I$ is the

porosity as a fraction, p is viscosity in cp, c, is total compressibility in psi-’, A

is area in ft*, and re. is the external radius in feet which should be based on

the distance to the farthest drainage boundary for the well. For large systems

or reservoirs with low permeability, very long stabilization times may be required.

Equation 5-128 assumes that productivity index does not change with flow

rate or time, and in some wells the flow rate will remain proportional to the

pressure drawdown over a wide range of flow rates. However, in many wells,

the direct relationship is not linear at high flow rates as shown in Figure 5-129.

The causes for the deviation in the straight-line behavior can include insufficient

producing times at each rate, an increase in gas saturation near the wellbore

caused by the pressure drop in that region, a decrease in permeability of oil

due to the presence of gas, a reduction in permeability due to changes in

formation compressibility, an increase in oil viscosity with pressure drop below

the bubble point, and possible turbulence at high rates of flow.

A plot of oil production rate versus bottomhole pressure, termed the inflow

performance relationship (IPR), was proposed as a method of analysis of flowing

and gas-lift wells [223]. Vogel [224] calculated dimensionless IPR curves for

solution gas reservoirs that covered a wide range of oil PVT and relative

permeability characteristics. From computer simulations, Vogel [224] showed that