Page 27 - Steam Turbines--Design, Applications, and Rerating by Heinz-Bloch, Murari-Singh

P. 27

8 Chapter One

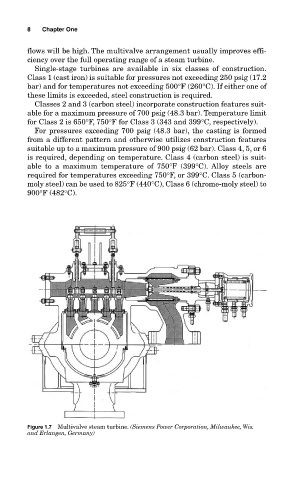

flows will be high. The multivalve arrangement usually improves effi-

ciency over the full operating range of a steam turbine.

Single-stage turbines are available in six classes of construction.

Class 1 (cast iron) is suitable for pressures not exceeding 250 psig (17.2

bar) and for temperatures not exceeding 500°F (260°C). If either one of

these limits is exceeded, steel construction is required.

Classes 2 and 3 (carbon steel) incorporate construction features suit-

able for a maximum pressure of 700 psig (48.3 bar). Temperature limit

for Class 2 is 650°F, 750°F for Class 3 (343 and 399°C, respectively).

For pressures exceeding 700 psig (48.3 bar), the casting is formed

from a different pattern and otherwise utilizes construction features

suitable up to a maximum pressure of 900 psig (62 bar). Class 4, 5, or 6

is required, depending on temperature. Class 4 (carbon steel) is suit-

able to a maximum temperature of 750°F (399°C). Alloy steels are

required for temperatures exceeding 750°F, or 399°C. Class 5 (carbon-

moly steel) can be used to 825°F (440°C), Class 6 (chrome-moly steel) to

900°F (482°C).

Figure 1.7 Multivalve steam turbine. (Siemens Power Corporation, Milwaukee, Wis.

and Erlangen, Germany)