Page 32 - Steam Turbines--Design, Applications, and Rerating by Heinz-Bloch, Murari-Singh

P. 32

Introduction 13

an existing boiler is replaced with one at higher pressure to gain addi-

tional generation and improved efficiency. A bottoming turbine, from a

process pressure to the condenser, is used to recover energy when pro-

cess heat needs are reduced either permanently or seasonally.

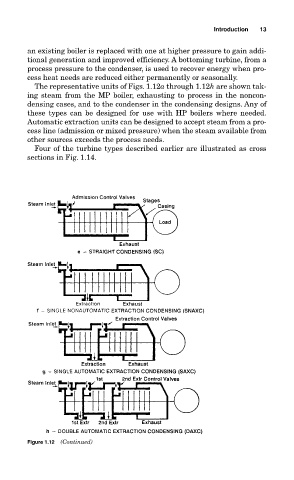

The representative units of Figs. 1.12a through 1.12h are shown tak-

ing steam from the MP boiler, exhausting to process in the noncon-

densing cases, and to the condenser in the condensing designs. Any of

these types can be designed for use with HP boilers where needed.

Automatic extraction units can be designed to accept steam from a pro-

cess line (admission or mixed pressure) when the steam available from

other sources exceeds the process needs.

Four of the turbine types described earlier are illustrated as cross

sections in Fig. 1.14.

Figure 1.12 (Continued)