Page 33 - Steam Turbines--Design, Applications, and Rerating by Heinz-Bloch, Murari-Singh

P. 33

14 Chapter One

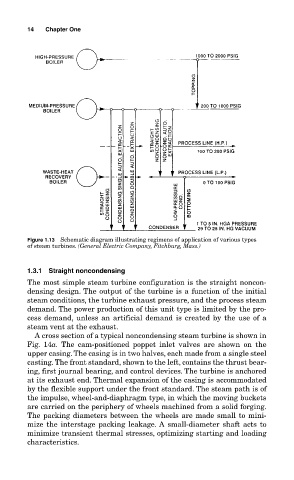

Figure 1.13 Schematic diagram illustrating regimens of application of various types

of steam turbines. (General Electric Company, Fitchburg, Mass.)

1.3.1 Straight noncondensing

The most simple steam turbine configuration is the straight noncon-

densing design. The output of the turbine is a function of the initial

steam conditions, the turbine exhaust pressure, and the process steam

demand. The power production of this unit type is limited by the pro-

cess demand, unless an artificial demand is created by the use of a

steam vent at the exhaust.

A cross section of a typical noncondensing steam turbine is shown in

Fig. 14a. The cam-positioned poppet inlet valves are shown on the

upper casing. The casing is in two halves, each made from a single steel

casting. The front standard, shown to the left, contains the thrust bear-

ing, first journal bearing, and control devices. The turbine is anchored

at its exhaust end. Thermal expansion of the casing is accommodated

by the flexible support under the front standard. The steam path is of

the impulse, wheel-and-diaphragm type, in which the moving buckets

are carried on the periphery of wheels machined from a solid forging.

The packing diameters between the wheels are made small to mini-

mize the interstage packing leakage. A small-diameter shaft acts to

minimize transient thermal stresses, optimizing starting and loading

characteristics.