Page 49 - Steam Turbines--Design, Applications, and Rerating by Heinz-Bloch, Murari-Singh

P. 49

30 Chapter Two

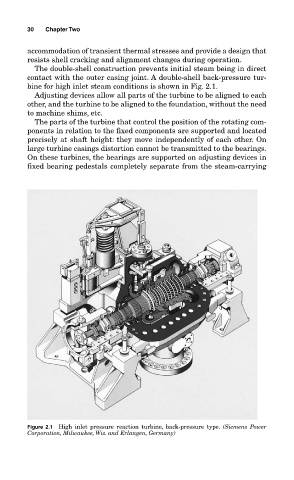

accommodation of transient thermal stresses and provide a design that

resists shell cracking and alignment changes during operation.

The double-shell construction prevents initial steam being in direct

contact with the outer casing joint. A double-shell back-pressure tur-

bine for high inlet steam conditions is shown in Fig. 2.1.

Adjusting devices allow all parts of the turbine to be aligned to each

other, and the turbine to be aligned to the foundation, without the need

to machine shims, etc.

The parts of the turbine that control the position of the rotating com-

ponents in relation to the fixed components are supported and located

precisely at shaft height: they move independently of each other. On

large turbine casings distortion cannot be transmitted to the bearings.

On these turbines, the bearings are supported on adjusting devices in

fixed bearing pedestals completely separate from the steam-carrying

Figure 2.1 High inlet pressure reaction turbine, back-pressure type. (Siemens Power

Corporation, Milwaukee, Wis. and Erlangen, Germany)