Page 152 - Steam Turbines Design, Applications, and Rerating

P. 152

Turbine Auxiliaries 133

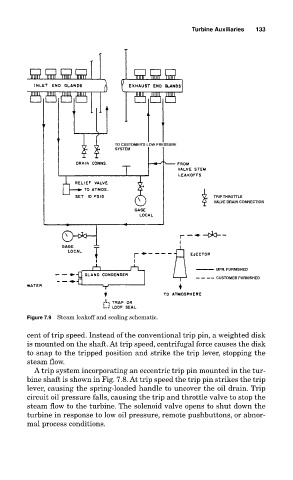

Figure 7.9 Steam leakoff and sealing schematic.

cent of trip speed. Instead of the conventional trip pin, a weighted disk

is mounted on the shaft. At trip speed, centrifugal force causes the disk

to snap to the tripped position and strike the trip lever, stopping the

steam flow.

A trip system incorporating an eccentric trip pin mounted in the tur-

bine shaft is shown in Fig. 7.8. At trip speed the trip pin strikes the trip

lever, causing the spring-loaded handle to uncover the oil drain. Trip

circuit oil pressure falls, causing the trip and throttle valve to stop the

steam flow to the turbine. The solenoid valve opens to shut down the

turbine in response to low oil pressure, remote pushbuttons, or abnor-

mal process conditions.