Page 154 - Steam Turbines Design, Applications, and Rerating

P. 154

Turbine Auxiliaries 135

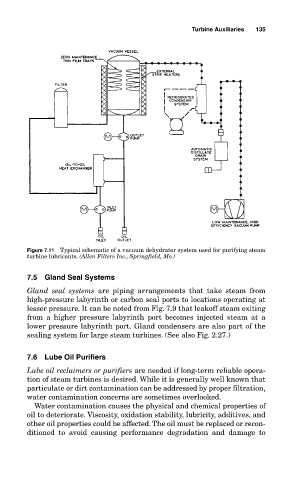

Figure 7.11 Typical schematic of a vacuum dehydrator system used for purifying steam

turbine lubricants. (Allen Filters Inc., Springfield, Mo.)

7.5 Gland Seal Systems

Gland seal systems are piping arrangements that take steam from

high-pressure labyrinth or carbon seal ports to locations operating at

lesser pressure. It can be noted from Fig. 7.9 that leakoff steam exiting

from a higher pressure labyrinth port becomes injected steam at a

lower pressure labyrinth port. Gland condensers are also part of the

sealing system for large steam turbines. (See also Fig. 2.27.)

7.6 Lube Oil Purifiers

Lube oil reclaimers or purifiers are needed if long-term reliable opera-

tion of steam turbines is desired. While it is generally well known that

particulate or dirt contamination can be addressed by proper filtration,

water contamination concerns are sometimes overlooked.

Water contamination causes the physical and chemical properties of

oil to deteriorate. Viscosity, oxidation stability, lubricity, additives, and

other oil properties could be affected. The oil must be replaced or recon-

ditioned to avoid causing performance degradation and damage to