Page 197 - Steam Turbines Design, Applications, and Rerating

P. 197

176 Chapter Ten

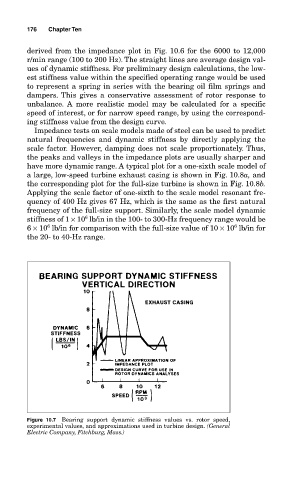

derived from the impedance plot in Fig. 10.6 for the 6000 to 12,000

r/min range (100 to 200 Hz). The straight lines are average design val-

ues of dynamic stiffness. For preliminary design calculations, the low-

est stiffness value within the specified operating range would be used

to represent a spring in series with the bearing oil film springs and

dampers. This gives a conservative assessment of rotor response to

unbalance. A more realistic model may be calculated for a specific

speed of interest, or for narrow speed range, by using the correspond-

ing stiffness value from the design curve.

Impedance tests on scale models made of steel can be used to predict

natural frequencies and dynamic stiffness by directly applying the

scale factor. However, damping does not scale proportionately. Thus,

the peaks and valleys in the impedance plots are usually sharper and

have more dynamic range. A typical plot for a one-sixth scale model of

a large, low-speed turbine exhaust casing is shown in Fig. 10.8a, and

the corresponding plot for the full-size turbine is shown in Fig. 10.8b.

Applying the scale factor of one-sixth to the scale model resonant fre-

quency of 400 Hz gives 67 Hz, which is the same as the first natural

frequency of the full-size support. Similarly, the scale model dynamic

6

stiffness of 1 × 10 lb/in in the 100- to 300-Hz frequency range would be

6

6

6 × 10 lb/in for comparison with the full-size value of 10 × 10 lb/in for

the 20- to 40-Hz range.

Figure 10.7 Bearing support dynamic stiffness values vs. rotor speed,

experimental values, and approximations used in turbine design. (General

Electric Company, Fitchburg, Mass.)