Page 196 - Steam Turbines Design, Applications, and Rerating

P. 196

Rotor Dynamics Technology 175

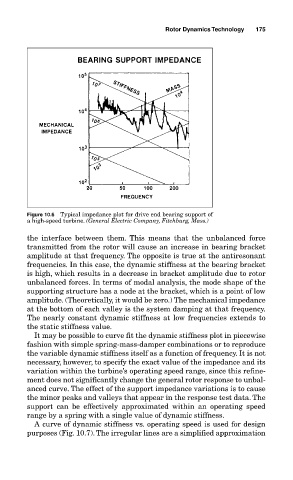

Figure 10.6 Typical impedance plot for drive end bearing support of

a high-speed turbine. (General Electric Company, Fitchburg, Mass.)

the interface between them. This means that the unbalanced force

transmitted from the rotor will cause an increase in bearing bracket

amplitude at that frequency. The opposite is true at the antiresonant

frequencies. In this case, the dynamic stiffness at the bearing bracket

is high, which results in a decrease in bracket amplitude due to rotor

unbalanced forces. In terms of modal analysis, the mode shape of the

supporting structure has a node at the bracket, which is a point of low

amplitude. (Theoretically, it would be zero.) The mechanical impedance

at the bottom of each valley is the system damping at that frequency.

The nearly constant dynamic stiffness at low frequencies extends to

the static stiffness value.

It may be possible to curve fit the dynamic stiffness plot in piecewise

fashion with simple spring-mass-damper combinations or to reproduce

the variable dynamic stiffness itself as a function of frequency. It is not

necessary, however, to specify the exact value of the impedance and its

variation within the turbine’s operating speed range, since this refine-

ment does not significantly change the general rotor response to unbal-

anced curve. The effect of the support impedance variations is to cause

the minor peaks and valleys that appear in the response test data. The

support can be effectively approximated within an operating speed

range by a spring with a single value of dynamic stiffness.

A curve of dynamic stiffness vs. operating speed is used for design

purposes (Fig. 10.7). The irregular lines are a simplified approximation