Page 31 - Steam Turbines Design, Applications, and Rerating

P. 31

12 Chapter One

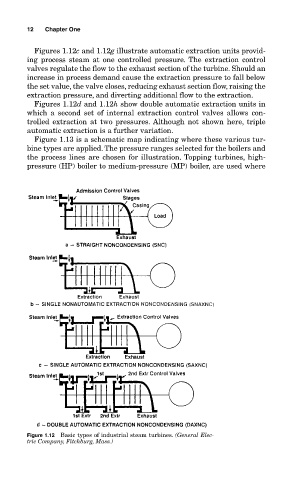

Figures 1.12c and 1.12g illustrate automatic extraction units provid-

ing process steam at one controlled pressure. The extraction control

valves regulate the flow to the exhaust section of the turbine. Should an

increase in process demand cause the extraction pressure to fall below

the set value, the valve closes, reducing exhaust section flow, raising the

extraction pressure, and diverting additional flow to the extraction.

Figures 1.12d and 1.12h show double automatic extraction units in

which a second set of internal extraction control valves allows con-

trolled extraction at two pressures. Although not shown here, triple

automatic extraction is a further variation.

Figure 1.13 is a schematic map indicating where these various tur-

bine types are applied. The pressure ranges selected for the boilers and

the process lines are chosen for illustration. Topping turbines, high-

pressure (HP) boiler to medium-pressure (MP) boiler, are used where

Figure 1.12 Basic types of industrial steam turbines. (General Elec-

tric Company, Fitchburg, Mass.)