Page 36 - Steam Turbines Design, Applications, and Rerating

P. 36

Introduction 17

(d)

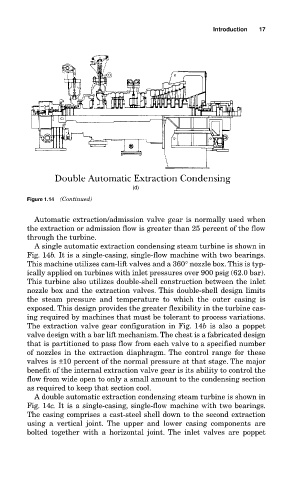

Figure 1.14 (Continued)

Automatic extraction/admission valve gear is normally used when

the extraction or admission flow is greater than 25 percent of the flow

through the turbine.

A single automatic extraction condensing steam turbine is shown in

Fig. 14b. It is a single-casing, single-flow machine with two bearings.

This machine utilizes cam-lift valves and a 360° nozzle box. This is typ-

ically applied on turbines with inlet pressures over 900 psig (62.0 bar).

This turbine also utilizes double-shell construction between the inlet

nozzle box and the extraction valves. This double-shell design limits

the steam pressure and temperature to which the outer casing is

exposed. This design provides the greater flexibility in the turbine cas-

ing required by machines that must be tolerant to process variations.

The extraction valve gear configuration in Fig. 14b is also a poppet

valve design with a bar lift mechanism. The chest is a fabricated design

that is partitioned to pass flow from each valve to a specified number

of nozzles in the extraction diaphragm. The control range for these

valves is ±10 percent of the normal pressure at that stage. The major

benefit of the internal extraction valve gear is its ability to control the

flow from wide open to only a small amount to the condensing section

as required to keep that section cool.

A double automatic extraction condensing steam turbine is shown in

Fig. 14c. It is a single-casing, single-flow machine with two bearings.

The casing comprises a cast-steel shell down to the second extraction

using a vertical joint. The upper and lower casing components are

bolted together with a horizontal joint. The inlet valves are poppet