Page 55 - Steam Turbines Design, Applications, and Rerating

P. 55

36 Chapter Two

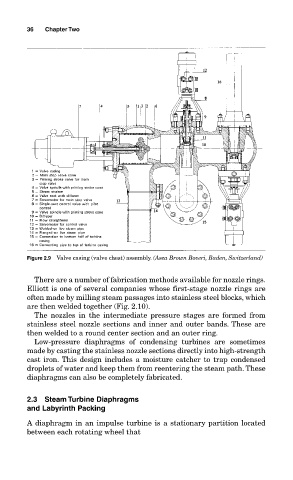

Figure 2.9 Valve casing (valve chest) assembly. (Asea Brown Boveri, Baden, Switzerland)

There are a number of fabrication methods available for nozzle rings.

Elliott is one of several companies whose first-stage nozzle rings are

often made by milling steam passages into stainless steel blocks, which

are then welded together (Fig. 2.10).

The nozzles in the intermediate pressure stages are formed from

stainless steel nozzle sections and inner and outer bands. These are

then welded to a round center section and an outer ring.

Low-pressure diaphragms of condensing turbines are sometimes

made by casting the stainless nozzle sections directly into high-strength

cast iron. This design includes a moisture catcher to trap condensed

droplets of water and keep them from reentering the steam path. These

diaphragms can also be completely fabricated.

2.3 Steam Turbine Diaphragms

and Labyrinth Packing

A diaphragm in an impulse turbine is a stationary partition located

between each rotating wheel that