Page 235 - Sustainability in the Process Industry Integration and Optimization

P. 235

212 Cha p te r N i n e

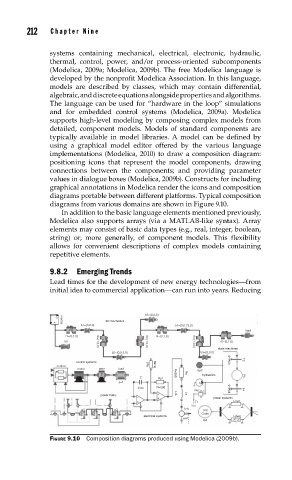

systems containing mechanical, electrical, electronic, hydraulic,

thermal, control, power, and/or process-oriented subcomponents

(Modelica, 2009a; Modelica, 2009b). The free Modelica language is

developed by the nonprofit Modelica Association. In this language,

models are described by classes, which may contain differential,

algebraic, and discrete equations alongside properties and algorithms.

The language can be used for “hardware in the loop” simulations

and for embedded control systems (Modelica, 2009a). Modelica

supports high-level modeling by composing complex models from

detailed, component models. Models of standard components are

typically available in model libraries. A model can be defined by

using a graphical model editor offered by the various language

implementations (Modelica, 2010) to draw a composition diagram:

positioning icons that represent the model components, drawing

connections between the components; and providing parameter

values in dialogue boxes (Modelica, 2009b). Constructs for including

graphical annotations in Modelica render the icons and composition

diagrams portable between different platforms. Typical composition

diagrams from various domains are shown in Figure 9.10.

In addition to the basic language elements mentioned previously,

Modelica also supports arrays (via a MATLAB-like syntax). Array

elements may consist of basic data types (e.g., real, integer, boolean,

string) or, more generally, of component models. This flexibility

allows for convenient descriptions of complex models containing

repetitive elements.

9.8.2 Emerging Trends

Lead times for the development of new energy technologies—from

initial idea to commercial application—can run into years. Reducing

b3={0,0,0}

y

3D mechanics

x

b1={0,0,0} b4={0,0.73,0}

Inertial

load

r1={0,1,0} r4={0,1,0}

b0 r2={1,0,0} r3={1,0,0} r5={1,0,0} r6={0,1,0}

state machines

b2={0,0.5,0} b5={0,0,0}

time>3 T2

control systems R=50

control Rp2

motor gear load

VolP

1 R=250 Ra hydraulics P4

C Rp1

J=1 q

C=C R=200 time>5

Rel T4

power trains L=L La

power systems

T1 Line1

p1 p2 p3 k=k 3rd

Order

electrical systems Line2

emf

G2

FIGURE 9.10 Composition diagrams produced using Modelica (2009b).