Page 308 - Sustainability in the Process Industry Integration and Optimization

P. 308

T y p i c a l P i t f a l l s a n d How t o Avo i d T h e m 285

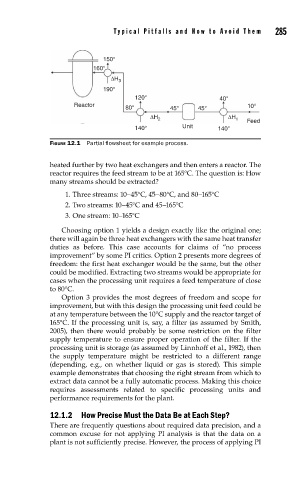

150°

160°

ΔH 3

190°

120° 40°

Reactor 80° 45° 45° 10°

ΔH 2 ΔH 1 Feed

140° Unit 140°

FIGURE 12.1 Partial fl owsheet for example process.

heated further by two heat exchangers and then enters a reactor. The

reactor requires the feed stream to be at 165°C. The question is: How

many streams should be extracted?

1. Three streams: 10–45°C, 45–80°C, and 80–165°C

2. Two streams: 10–45°C and 45–165°C

3. One stream: 10–165°C

Choosing option 1 yields a design exactly like the original one;

there will again be three heat exchangers with the same heat transfer

duties as before. This case accounts for claims of “no process

improvement” by some PI critics. Option 2 presents more degrees of

freedom: the first heat exchanger would be the same, but the other

could be modified. Extracting two streams would be appropriate for

cases when the processing unit requires a feed temperature of close

to 80°C.

Option 3 provides the most degrees of freedom and scope for

improvement, but with this design the processing unit feed could be

at any temperature between the 10°C supply and the reactor target of

165°C. If the processing unit is, say, a filter (as assumed by Smith,

2005), then there would probably be some restriction on the filter

supply temperature to ensure proper operation of the filter. If the

processing unit is storage (as assumed by Linnhoff et al., 1982), then

the supply temperature might be restricted to a different range

(depending, e.g., on whether liquid or gas is stored). This simple

example demonstrates that choosing the right stream from which to

extract data cannot be a fully automatic process. Making this choice

requires assessments related to specific processing units and

performance requirements for the plant.

12.1.2 How Precise Must the Data Be at Each Step?

There are frequently questions about required data precision, and a

common excuse for not applying PI analysis is that the data on a

plant is not sufficiently precise. However, the process of applying PI