Page 369 - Sustainability in the Process Industry Integration and Optimization

P. 369

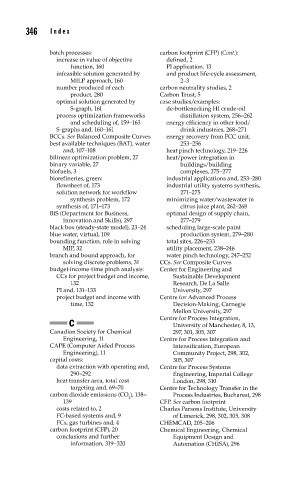

346 Inde x

batch processes: carbon footprint (CFP) (Cont.):

increase in value of objective defined, 2

function, 160 PI application, 13

infeasible solution generated by and product life-cycle assessment,

MILP approach, 160 2–3

number produced of each carbon neutrality studies, 2

product, 280 Carbon Trust, 5

optimal solution generated by case studies/examples:

S-graph, 161 de-bottlenecking HI crude-oil

process optimization frameworks distillation system, 256–262

and scheduling of, 159–163 energy efficiency in other food/

S-graphs and, 160–161 drink industries, 268–271

BCCs. See Balanced Composite Curves energy recovery from FCC unit,

best available techniques (BAT), water 253–256

and, 107–108 heat pinch technology, 219–226

bilinear optimization problem, 27 heat/power integration in

binary variable, 27 buildings/building

biofuels, 3 complexes, 275–277

biorefineries, green: industrial applications and, 253–280

flowsheet of, 173 industrial utility systems synthesis,

solution network for workflow 271–275

synthesis problem, 172 minimizing water/wastewater in

synthesis of, 171–173 citrus juice plant, 262–268

BIS (Department for Business, optimal design of supply chain,

Innovation and Skills), 297 277–279

black box (steady-state model), 23–24 scheduling large-scale paint

blue water, virtual, 109 production system, 279–280

bounding function, role in solving total sites, 226–233

MIP, 32 utility placement, 238–246

branch and bound approach, for water pinch technology, 247–252

solving discrete problems, 31 CCs. See Composite Curves

budget-income-time pinch analysis: Center for Engineering and

CCs for project budget and income, Sustainable Development

132 Research, De La Salle

PI and, 131–133 University, 297

project budget and income with Centre for Advanced Process

time, 132 Decision-Making, Carnegie

Mellon University, 297

C C Centre for Process Integration,

University of Manchester, 8, 13,

Canadian Society for Chemical 297, 301, 305, 307

Engineering, 11 Centre for Process Integration and

CAPE (Computer Aided Process Intensification, European

Engineering), 11 Community Project, 298, 302,

capital costs: 305, 307

data extraction with operating and, Centre for Process Systems

290–292 Engineering, Imperial College

heat transfer area, total cost London, 298, 310

targeting and, 69–70 Centre for Technology Transfer in the

carbon dioxide emissions (CO ), 138– Process Industries, Bucharest, 298

2

139 CFP. See carbon footprint

costs related to, 2 Charles Parsons Institute, University

FC-based systems and, 9 of Limerick, 298, 302, 305, 308

FCs, gas turbines and, 4 CHEMCAD, 205–206

carbon footprint (CFP), 20 Chemical Engineering, Chemical

conclusions and further Equipment Design and

information, 319–320 Automation (CHISA), 296