Page 104 - Sustainable On-Site CHP Systems Design, Construction, and Operations

P. 104

82 CHP B a s i c s

heat recovered from power generation can still be used without necessarily directly

meeting the load quality requirements. The lower temperature condenser water pro-

duced by the absorber allows the use of a centrifugal chiller at an efficiency of 0.7 kW/

ton. Without the CHP chiller, the facility would require a screw chiller using condenser

water from a cooling tower which would have an efficiency of 1.5 kW/ton.

The chiller cooling tower is an integral part of the CHP system and can be used to

increase system efficiency. A differentiating characteristic for CHP design versus standard

HVAC design is that the CHP chiller operates at or close to full load through varying ambi-

ent conditions. HVAC design is focused on being able to meet the facility peak loads during

peak ambient conditions and maximizing system efficiency through various part load con-

ditions. For steam turbine chillers, liquid desiccants, ammonia/water absorbers and to a

lesser extent, single-stage LiBr absorbers, the full load efficiency can be significantly increased

at lower condenser water temperatures. This is especially valuable when the CHP system

addresses both cooling and heating needs. The increase in chiller efficiency allows more of

the heat recovered from the engine to be directed to offsetting heating.

When electric loads are constant but thermal loads vary widely, thermal energy

storage can be used to harmonize the facility thermal load requirements with the CHP

system thermal output. Where electric loads also vary significantly, electric chillers in

combination with thermal energy storage may be used to level electric and thermal load

profiles for high 24-hour load factor on the CHP system.

Thermal Energy Storage

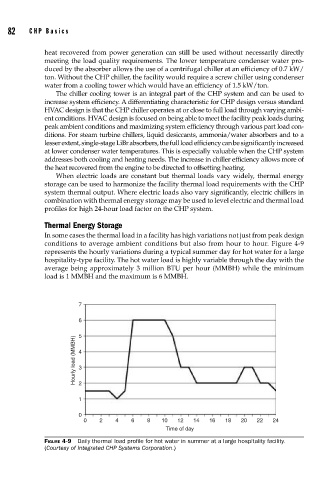

In some cases the thermal load in a facility has high variations not just from peak design

conditions to average ambient conditions but also from hour to hour. Figure 4-9

represents the hourly variations during a typical summer day for hot water for a large

hospitality-type facility. The hot water load is highly variable through the day with the

average being approximately 3 million BTU per hour (MMBH) while the minimum

load is 1 MMBH and the maximum is 6 MMBH.

7

6 5

Hourly load (MMBH) 4 3

1 2

0

0 2 4 6 8 10 12 14 16 18 20 22 24

Time of day

FIGURE 4-9 Daily thermal load profi le for hot water in summer at a large hospitality facility.

(Courtesy of Integrated CHP Systems Corporation.)