Page 151 - Sustainable On-Site CHP Systems Design, Construction, and Operations

P. 151

124 CHP B a s i c s

HRSG

drum Stack No x /O 3

monitor

Fuel Superheater Boiler Economizer

Air

FM

SCR

Exhaust

gas

Gas turbine

TIC

No x

monitor

Accumulator

Vaporizer

FC

S

Ammonia storage tank

NH 3

NH 3 /Air mixer flow- Legend:

Dillution air blower

control FC - Flow control

valve TIC - Temp indicator control

FM - Fuel meter

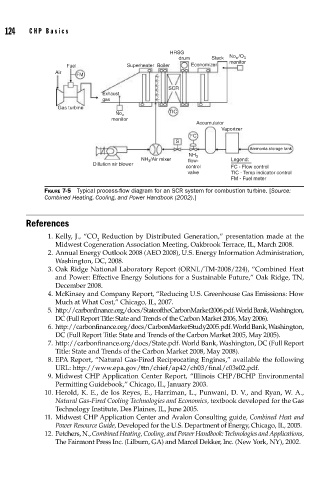

FIGURE 7-5 Typical process-fl ow diagram for an SCR system for combustion turbine. [Source:

Combined Heating, Cooling, and Power Handbook (2002).]

References

1. Kelly, J., “CO Reduction by Distributed Generation,” presentation made at the

2

Midwest Cogeneration Association Meeting, Oakbrook Terrace, IL, March 2008.

2. Annual Energy Outlook 2008 (AEO 2008), U.S. Energy Information Administration,

Washington, DC, 2008.

3. Oak Ridge National Laboratory Report (ORNL/TM-2008/224), “Combined Heat

and Power: Effective Energy Solutions for a Sustainable Future,” Oak Ridge, TN,

December 2008.

4. McKinsey and Company Report, “Reducing U.S. Greenhouse Gas Emissions: How

Much at What Cost,” Chicago, IL, 2007.

5. http://carbonfinance.org/docs/StateoftheCarbonMarket2006.pdf. World Bank, Washington,

DC (Full Report Title: State and Trends of the Carbon Market 2006, May 2006).

6. http://carbonfinance.org/docs/CarbonMarketStudy2005.pdf. World Bank, Washington,

DC (Full Report Title: State and Trends of the Carbon Market 2005, May 2005).

7. http://carbonfinance.org/docs/State.pdf. World Bank, Washington, DC (Full Report

Title: State and Trends of the Carbon Market 2008, May 2008).

8. EPA Report, “Natural Gas-Fired Reciprocating Engines,” available the following

URL: http://www.epa.gov/ttn/chief/ap42/ch03/final/c03s02.pdf.

9. Midwest CHP Application Center Report, “Illinois CHP/BCHP Environmental

Permitting Guidebook,” Chicago, IL, January 2003.

10. Herold, K. E., de los Reyes, E., Harriman, L., Punwani, D. V., and Ryan, W. A.,

Natural Gas-Fired Cooling Technologies and Economics, textbook developed for the Gas

Technology Institute, Des Plaines, IL, June 2005.

11. Midwest CHP Application Center and Avalon Consulting guide, Combined Heat and

Power Resource Guide, Developed for the U.S. Department of Energy, Chicago, IL, 2005.

12. Petchers, N., Combined Heating, Cooling, and Power Handbook: Technologies and Applications,

The Fairmont Press Inc. (Lilburn, GA) and Marcel Dekker, Inc. (New York, NY), 2002.