Page 26 - Sustainable On-Site CHP Systems Design, Construction, and Operations

P. 26

Overview 5

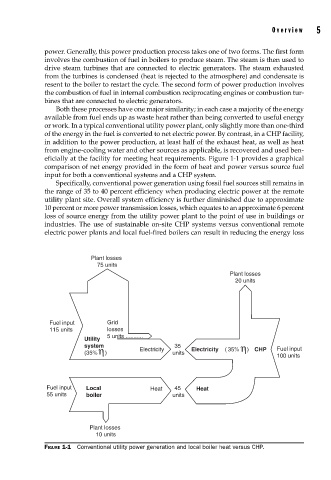

power. Generally, this power production process takes one of two forms. The first form

involves the combustion of fuel in boilers to produce steam. The steam is then used to

drive steam turbines that are connected to electric generators. The steam exhausted

from the turbines is condensed (heat is rejected to the atmosphere) and condensate is

resent to the boiler to restart the cycle. The second form of power production involves

the combustion of fuel in internal combustion reciprocating engines or combustion tur-

bines that are connected to electric generators.

Both these processes have one major similarity; in each case a majority of the energy

available from fuel ends up as waste heat rather than being converted to useful energy

or work. In a typical conventional utility power plant, only slightly more than one-third

of the energy in the fuel is converted to net electric power. By contrast, in a CHP facility,

in addition to the power production, at least half of the exhaust heat, as well as heat

from engine-cooling water and other sources as applicable, is recovered and used ben-

eficially at the facility for meeting heat requirements. Figure 1-1 provides a graphical

comparison of net energy provided in the form of heat and power versus source fuel

input for both a conventional systems and a CHP system.

Specifically, conventional power generation using fossil fuel sources still remains in

the range of 35 to 40 percent efficiency when producing electric power at the remote

utility plant site. Overall system efficiency is further diminished due to approximate

10 percent or more power transmission losses, which equates to an approximate 6 percent

loss of source energy from the utility power plant to the point of use in buildings or

industries. The use of sustainable on-site CHP systems versus conventional remote

electric power plants and local fuel-fired boilers can result in reducing the energy loss

Plant losses

75 units

Plant losses

20 units

Fuel input Grid

115 units losses

5 units ...........

Utility

(35% ) η Electricity units Electricity ( 35% ) CHP Fuel input

system 35 η

100 units

Fuel input Local Heat 45 Heat

55 units boiler units

Plant losses

10 units

FIGURE 1-1 Conventional utility power generation and local boiler heat versus CHP.