Page 31 - Sustainable On-Site CHP Systems Design, Construction, and Operations

P. 31

10 CHP B a s i c s

with the best return on investment (ROI) and/or outcome typically requires a critical

analysis of probable operating scenarios, which rely heavily upon historical operating

information along with facility current and foreseeable needs.

Use of CHP is generally more attractive within larger buildings with multiple use

occupancies and/or longer daily operating hours and particularly in urban areas where

high electrical and somewhat lower gas rates prevail. CHP is also more common where

utilization of available waste heat for cooling production can minimize peak electrical

demand by offsetting electric-drive chiller operation.

Where greater availability and selection among low-cost microturbines exist, inter-

est in both co- and trigeneration is increasing. Additionally, where opportunities for

larger combined (i.e., hybrid) operations exist, both co- and trigeneration are provided

with further incentives. Such opportunities have created greater owner interest. Yet

until recently, CHP applications were often overlooked by facility owners. Of course,

challenges sometimes arise with noise reduction, available gas pressure at the site,

particularly for CTGs, and lack of staff experience. Combined gas and electrical utili-

ties tend to be more flexible, particularly when CHP facilities are intended to operate

in parallel with the serving utility. Sometimes, excessive utility interconnect require-

ments or owner disappointment with income streams can serve as a barrier to CHP

implementation.

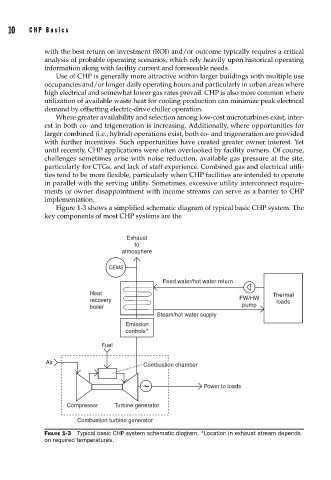

Figure 1-3 shows a simplified schematic diagram of typical basic CHP system. The

key components of most CHP systems are the

Exhaust

to

atmosphere

CEMS

Feed water/hot water return

Heat Thermal

recovery FW/HW loads

boiler pump

Steam/hot water supply

Emission

controls ∗

Fuel

Air

Combustion chamber

~ Power to loads

Compressor Turbine generator

Combustion turbine generator

FIGURE 1-3 Typical basic CHP system schematic diagram. ∗ Location in exhaust stream depends

on required temperatures.